Lithonplus uses new production method for

L-shaped retaining walls

On account of a new patented production method, Lithonplus Steinmanufaktur has succeeded for the first time with the invention of the „L-Tec System Angle“ in the industrial manufacture of large L-shaped retaining walls with impressive advantages, together with the machine and plant manufacturing specialists for the precast industry Ebawe Anlagentechnik GmbH and Tecnocom Spa.

On account of a new patented production method, Lithonplus Steinmanufaktur has succeeded for the first time with the invention of the „L-Tec System Angle“ in the industrial manufacture of large L-shaped retaining walls with impressive advantages: they are formwork-smooth all round and much easier to transport, lift and erect. The company took five years to develop this new manufacturing method, which it has successfully implemented together with the machine and plant manufacturing specialists for the precast industry Ebawe Anlagentechnik GmbH and Tecnocom Spa, both of which belong to the Progress Group.

More than 100 years of concrete experience

Lithonplus Steinmanufaktur, headquartered in Lingenfeld, Rhineland-Palatinate, is a subsidiary of HeidelbergCement AG and Schwenk KG. The company has concentrated their traditional activities in the field of concrete products since 2004 and can look back on over one hundred years of experience. At 16 locations all over Germany, the company produces and distributes an extensive range of high-quality concrete products for the layout of paths, squares, patios, drives and front gardens of houses. A team of around 600 employees generate an annual turnover of more than 120 million euros.

Success with the right philosophy

Apart from a distinct passion for concrete, the success philosophy in the past years has focused on the manufacture of high-quality products and a high level of customer orientation.

Lithonplus says: „For us, concrete means unlimited design freedom and a rich diversity due to an endless number of possible shapes and colours. Our passion is to use this freedom and to turn it with fantasy into convincing product lines.“ All dealings revolve around strict customer orientation: „Our goal is absolute customer satisfaction and long-term customer retention. We wish to achieve that with convincing products, smooth processes and the uncompromising implementation of all requirements.“ One of the most important criteria in this context is the manufacture of high-quality products. „The machine-manufactured products are therefore produced on modern plants with the latest technology“, says Rust.

The innovative L-TEC System Angle

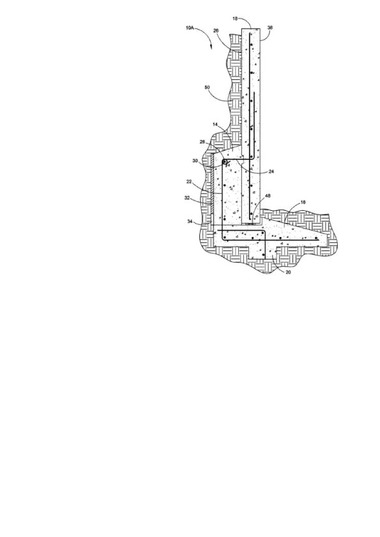

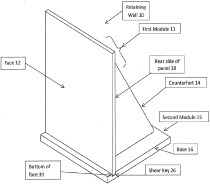

Gregory Trautmann and Wilfried Polle, both managing directors at Lithonplus, recall that the desire to also implement these high company standards in the development and production of large L-shaped retaining walls demanded a great deal of innovative force from the company: „It took five years to develop the innovative plant for the optimal production of high-quality concrete elements.“ The goal was to find an automated alternative to the traditional manual production of L-shaped retaining walls, often also referred to as system angles. In addition, the universally usable L-shaped retaining walls were to have fair-faced concrete quality all round apart from the face on which they stand and - unlike conventional manufacturing methods - not exhibit any conicity. Following the long development period, the result has impressed planners and product users alike. In the development of the L-Tec System Angle, the company succeeded in realizing all these goals as well as further innovations:

Easy and uncomplicated handling: The trick is the suspension point of the L-shaped retaining wall, which is placed at the centre of gravity. As a result, the L-shaped retaining wall balances itself automatically during handling and is much easier than usual to lift and transport. Setting down on the foundations is quickly done, since energy-sapping alignment and adjustment are largely avoided.

Maximum fair-faced concrete quality SB4 all round: The maximum fair-faced concrete quality, class 4, is achieved all round with the L-shaped retaining walls. L-TEC System Angles therefore also impress as visual highlights and are of interest for extended areas of application, e.g. as a wall divider that is visible on both sides.

Flawless shaping: Formwork-related conicity is consigned to the past. L-Tec System Angles have a constant width over their entire height. L-shaped retaining walls placed alongside one another have the same joint width from top to bottom. The circumferential chamfers are reduced and of the same size. The formation of a dummy joint for 99 cm-wide elements was consciously omitted.

Ideal for traffic areas where de-icing salt is used: L-TEC System Angles conform to exposure class XF4, which means that they are suitable for applications where stress due to the use of deicing chemicals can be expected. This standard ensures planning and implementation security for all environmental conditions. In addition, the exposure class XF4 is prescribed for installation in traffic areas.

Quality products through automated production technology

Following a long and careful examination of various machine and plant manufacturers, Lithonplus chose to cooperate with Ebawe Anlagentechnik GmbH and Tecnocom Spa, both companies from the Progress Group, as its partners for the development of a highly automated production system for the manufacture of the new L-TEC System Angle.

The two partners developed for the first time a special circulation plant, tailored to Lithonplus‘ needs for the production of L-shaped retaining walls, in combination with special moulds with which the production of different L-shaped retaining walls with a length of 49 cm or 99 cm and heights of between 55 cm and 305 cm was possible without the conventional conicity of the elements.

A bespoke seven-stage production process allowed the manufacture of the new system angles to be automated to the highest degree. Following the cleaning and oiling of the special moulds, the concreting process takes place fully automatically with the aid of a fill-quantity monitor and a height-adjustable concrete distributor that can be adapted individually to the different mould heights. Several L-shaped retaining walls are concreted simultaneously.

The curing of the elements in a special curing chamber and the removal of the finished parts from the manufacturing process are also automated. The high degree of automation enables the company to operate a multi-shift system alongside the two-shift system, resulting in a significant increase in capacity with far fewer staff and much higher quality in comparison with traditional manufacturing methods.

Automation by the EBOS control system

The EBOS control system is the new centrepiece of the plant and manages all important functions. The system also featuresseveral extended capabilities, such as the automatic management of the curing chamber, the printout of reports and production analyses, the graphic performance analyzer for the further optimization of production, the printing of labels and the management of the storage yard.

Concluding evaluation

Jürgen Rust, section manager for L-shaped retaining walls at Lithonplus, is delighted with the successes achieved in the partnership between Lithonplus and the Progress Group companies. „We have succeeded in creating a unique product in combination with an extraordinary, highly automated production plant. Never before has it been possible to manufacture L-shaped retaining walls in such a variety and quality and at such a high speed in a plant. We therefore regard the development of the market and our positioning in it as being very positive for the future.“