Intelligent adapters for efficient handling in precast plants

The introduction of modern magnetic technology in modern precast concrete plants was followed by numerous adapter solutions for connecting and securely fixing in place magnet and form fabric. One of these was the “Speedy” Uniadapter-Set, a standard adapter solution that the company brought to the market. Since then, it is used by the precast concrete industry in combination with a Euro RTM shuttering magnet for fixing fibrous concrete upstands for balconies and parapets as well as for wooden formwork.

The further developed Speedy GF for fibrous concrete and Speedy H for wood was presented to precasters only a few years later. The special feature of these products was the integration of the switchable magnetic box with the at the time newly patented Ratec Automatic Magnet System. This adapter gives workers in production the possibility to precisely calibrate the position of fibrous concrete upstands prior to activating the magnet.

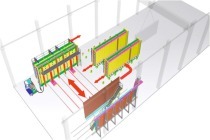

Application in precast floor plate and double wall production

Due to the integration of the Pro Magnet in the Ratec Automatic Magnet System and its r easy adjustment prior to activation, the Speedy was soon widely used by manufacturers of precast floor plates and double walls, where they are also used for fixing windows and doors.

One decade later, the Ratec development team, in cooperation with a customer, once again tackled the further development of the Speedy. The catalog of specification requirements listed the following objectives: The Speedy should take up as little space as possible on the pallet edge; no hammer should be required for fixing it in place. The system should be simple and stable, allowing for maximum flexibility, without weighing too much. The manipulations required for switching the Speedy on and off should be reduced to a minimum. The Speedy should be able to clamp two upstands on the abutment simultaneously; the upstands should remain fixed in place during vibration and shaking processes, and must not become damaged during demolding.

The Speedy GF-S was thoroughly tested for its fitness for use in concrete plants and was further optimized. The result is a compact adapter for fixing all standard fibrous concrete upstands of a wide range of manufacturers. The clamping range can be infinitely adjusted from 0 to 35 mm. A special upper add-on part was developed for solid concrete upstands, whose clamping range can be adjusted from 30 mm to 75 mm.

During testing, a further application of the Speedy GF-S was developed. Using an attachment that can be held in place with a clamp, embedded parts used in precast production can be fixed to the pallet. The clamp is removed prior to screeding so that the embedded parts are not interfered with.

Further rationalization of workflow

With the Speedy GF-S, Ratec achieved a further step in rationalizing workflows. The Speedy GF-S rests easily in the hand and its high-quality design is very robust and compact. The new design can be used lengthwise and crosswise so that it is now possible to manufacture elements on the pallet that are approx. 150 larger in size.

Another advantage is the reduction in shuttering times, the cycle time connected therewith and the resulting increased performance per m². The development is a further step that ensures the necessary investment security and future flexibility.