Helmut Faber retires

Helmut Faber joined the company Scholz in September of 1996. He had brought to Scholz extensive know-how about the subject of coloring concrete. At that time, his customers profited from his broad knowledge of concrete colors and concrete itself, because the focus on application was and is to this day of particular importance to Helmut Faber.

Helmut Faber set up the Applications Technology Department in the Partenstein Plant in Germany. In doing so, he established what would characterize the company for decades: customer orientation. This Applications Technology Department, the heart of which is a paving block plant (Schauer and Häberle) and a concrete laboratory, enabled Harold Scholz to process customer enquiries with a close focus on application and by utilizing the customers’ own formulas.

Responsible for development of an in-house dosing system

Helmut Faber never associated colored concrete exclusively with its pigment. In order to be able to successfully utilize color in the concrete plant, it is always essential to consider the pigment – in connection with the dosing technology. Helmut Faber was responsible for development of in-house dosing systems.

Systems for liquid colors and, most recently, for work with pigment granules. In the area of dosing technology, Helmut Faber extensively profited from his qualifications in agricultural engineering, for which he received a master’s degree at Stuttgart Hohenheim University.

Networking as his great strength

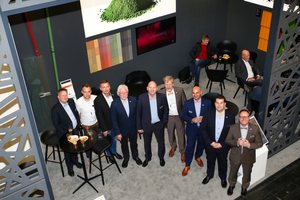

In the company, Helmut Faber was surrounded with many colleagues who shared their know-how with him. “You have to look each other in the eye,” which was his motto within the company as well as outside at trade shows, at congresses and during association meetings. Together with customers, and in particular with the leading manufacturers of dosing technology, Helmut Faber was always in dialog and therefore always up to date. With this philosophy, with intensive orientation to application and customers, by his networking and with his grasp of dosing technology, Helmut Faber was very successfully hard at work, wherever he was, for three decades in matters of colored concrete.

“To picture the company Scholz and colored concrete without Helmut Faber is extremely difficult,” says Dr. Peter Weber of the company Scholz. “Especially for me, said Dr. Weber, who can call Helmut both his friend and mentor. So, we wish Helmut Faber in the name of all Scholz colleagues all the conceivable best for his retirement. We are glad and proud that Helmut will continue to make available to us his extensive knowledge and abilities as friend and as colleague.”

CONTACT

Harold Scholz & Co. GmbH

Ickerottweg 30

45665 Recklinghausen/Germany

+49 2361 9888-0