Fully automated bending shops for the future

The ongoing trend towards automation is also increasingly gaining ground in reinforcing steel processing. Whereas work in a bending shop had been very hard and physically demanding 30 years ago, this situation has since improved significantly thanks to the advent of state-of-the-art machinery such as automatic stirrup benders as well as shearlines and bending units.

In the recent past, various factors have prompted Pedax to continue to push things forward towards implementing a fully automated bending shop design. For steel traders and precast businesses alike, it is becoming increasingly difficult to hire appropriately skilled and trained shop-floor staff. Add to this the reluctance of many people to perform this hard and dirty work. Also, compliance with more and more stringent health and safety requirements must be ensured amid increasing cost pressure owing to constantly rising wages. Long-established processes thus need to be questioned and rethought.

Fully automatic bar feed

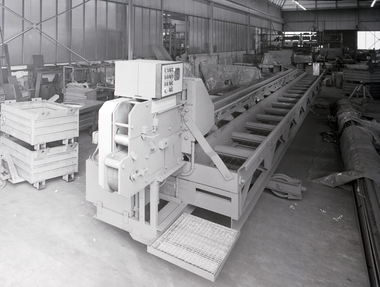

The Autender M logistics system supplied by Pedax is an important building block towards ensuring unmanned operation of stationary shearlines. In a fully automatic process, the unit feeds bars into the tried-and-tested Cadormatic shearlines, which have been in use for many decades. The Autender M moves on rails running above a stationary material compartment. The system uses a magnet to lift the required bars out of the compartment, as well as laser equipment to count them. In the next step, it places the counted bars on the infeed conveyor of the connected shearline with pinpoint precision.

Thus, the automated cycle already starts with feeding material into the production line, eliminating the need for the physically exhausting, error-prone manual insertion of bars. Just a single operator is required for monitoring the process and ensuring that sufficient quantities are stored for processing, and for replenishing the material compartment if and when required. The laser unit will detect any bar with an incorrect diameter placed in the empty compartment. In each counting step, bar diameters will be checked against the relevant specification. Thus, this smooth interplay of process steps requiring fewer staff inevitably leads to a significant increase in the “tonnage per employee”. Repeated operator errors are eliminated and lost-time injuries reduced dramatically.

Increasing operational efficiency

Nowadays, integrating optimization software, logistics components such as pocket systems, chain conveyors, and automatic bundling and labeling stations makes it possible to automate a major part of previously manual work steps. Bars to be bent can be arranged in pre-packaged bundles and conveyed all the way through to the bender. Bars of equal length are bundled, labeled and transported into collection troughs, and loaded directly onto trucks from there.

The Autender M logistics system has been designed for common material lengths of up to 18 m. Depending on the plant layout and other needs, it can be customized to the specific factory environment. The system can also be retrofitted to existing lines.

The requirements for reinforcing steel processing are becoming increasingly complex, in combination with more and more demanding tasks and work steps. Pedax provides precast producers with the opportunity of fully utilizing the benefits of automatic processes in order to increase their operational efficiency.

Interested attendees of this year’s bauma trade show in Munich are invited to visit the Pedax stand C3.214 to learn more about Cadormatic shearlines and automatic material feed through the Autender M system.