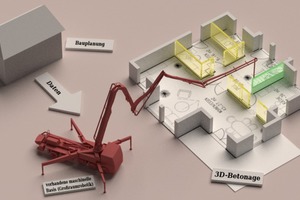

Formwork-free, continuous, monolithic construction using Concrete 3D Printing

Concrete is the world’s most widely used construction material; currently more than half of it is ready-mix concrete (46 mio. m3 in Germany). Formwork is needed for placing most types of concrete, especially ready-mix concrete. The use of formwork often leads to high material, labor and machinery costs in addition to considerable time delays and negative environmental impact. Thus, formwork-free construction methods have great economic and technical potential in concrete construction. Another significant advantage of formwork-free construction is its great geometrical flexibility. This article...

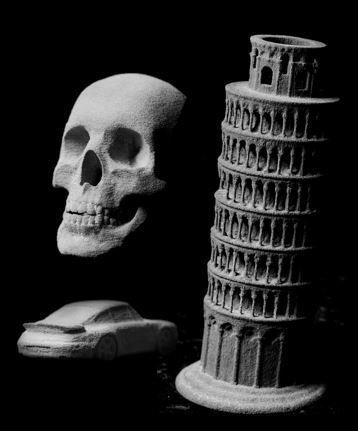

![→ 1 3D-printed structural elements by (left) Contour Crafting [1] and (right) D-Shape technology [3]](https://www.bft-international.com/imgs/tok_a428e3f5fc5552b3d76a272bcc73bbbf/w300_h200_x400_y300_103979977_5a9c039a81.jpg)