A milestone in 3D concrete printing: The White Tower of Mulegns

Tor Alva (“The White Tower”) is the tallest 3D-printed building in the world. This tower was designed for the Origen cultural foundation in collaboration with ETH Zurich and has recently been inaugurated in the village of Mulegns in the Swiss Alps. Our deputy editor-in-chief, Karla Knitter, attended the opening ceremony and is currently drafting a detailed project report to be published in the forthcoming edition of our „Beton Bauteile” yearbook 2026. This article provides an abstract focusing on innovative 3D printing.

Symbiosis of art and research

The symbiosis of artistic expression, digital research, and contemporary architecture has given rise to a unique building. The tower sets a new benchmark thanks to the use of material-efficient, 3D-printed reinforced concrete, which enables a unique architectural form.

Including the existing historic base, Tor Alva is 30 m high and has a diameter of 7 to 9 m. The tower features 32 custom-designed columns and consists of 2,500 printed concrete layers, each 10 mm high and 15 to 20 mm deep. The estimated printing time was 900 hours. The White Tower will be used for cultural events and performances hosted by the Origen Foundation. The domed hall is 8 m high and seats 32 spectators. The total cost of the project amounted to CHF 4.4 million (EUR 4.7 million).

Load-bearing reinforced 3D-printed concrete

The construction of the tower was to make a substantial contribution to the sustainable transformation of the construction industry. “We are facing major challenges, including the reduction of emissions, the growing demand for buildings, and labor shortage, to name but three of them. We can find the answers to these challenges together, including through radical digitalization of the construction industry,” said architect Prof. Benjamin Dillenburger on the occasion of the opening ceremony.

3D-printed concrete has so far mainly been used for non-structural elements. This was due to the lack of mechanical models and design rules that consider the anisotropic properties of 3D-printed concrete that result from its layering, as well as tried and tested concepts for reinforcement integration and models describing the interaction between reinforcement and 3D-printed concrete.

Comprehensive research was conducted at ETH Zurich to address these issues and fully exploit the potential of digital fabrication with concrete for load-bearing elements. First, a structural design concept and mechanical models for 3D-printed reinforced concrete were developed and validated experimentally on reduced-scale and full-scale 3D-printed reinforced concrete columns. Second, the interaction between reinforcement and 3D-printed concrete was investigated on two series of 3D-printed reinforced concrete tension members. Finally, a new material test for 3D-printed concrete, the so-called modified shear test, was established. This relatively simple test makes it possible to quantify the influence of the layer interfaces of 3D-printed concrete, including dry joints and cold joints, i.e. layers produced with a certain time lag due to interruptions of the printing process.

The work steps referred to above made it possible to reinforce the 3D-printed concrete of the White Tower with steel rebar and prestressing tendons to ensure a mechanical behavior similar to conventional reinforced concrete, thus adhering to applicable structural codes and standards. Accordingly, the White Tower is the world’s first multi-story building to use fully load-bearing, reinforced 3D-printed concrete.

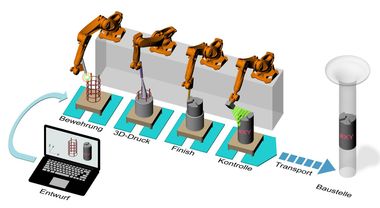

Reinforcement integrated in an automated process

During the printing process, steel reinforcement was integrated into the 3D-printed columns. For this purpose, two robots work together: One of them extrudes concrete layer by layer to create complex free-form elements, while the other inserts the reinforcement between these layers. This makes the 3D-printed structure fully load-bearing. Since concrete is only used where it is needed for structural purposes, this formwork-free fabrication method significantly reduces material consumption compared to conventional concrete pouring techniques.

The most important innovation of this process is the automated integration of reinforcement during the 3D printing process. Two robots work in tandem to achieve this goal: One of them continuously applies fresh concrete, while the other places reinforcement between the concrete layers. Once the thin-walled hollow bodies have been printed, longitudinal reinforcing bars are inserted into vertical channels, which are then filled with concrete. This robotic production process enables the use of 3D-printed concrete in a fully load-bearing and load-transferring manner.

Formwork-free, material-efficient process

In 3D concrete printing, a robotic arm successively applies thin layers of soft concrete through a nozzle. The material is soft enough to bond and form continuous, homogeneous components, but it also hardens quickly enough to support subsequently applied layers. The printing material is based on a multi-component technology that combines white concrete with a stabilizer and an accelerator for fast curing, which makes it possible to produce free-form elements with large overhangs. The 3D concrete filament used in the process is applied in 25 mm wide and 8 mm high layers, forming a continuous printing path of about 5,000 m per column.

Each column cross-section consists of three filaments: The outer filament shows the decorative structure referred to above, the center layer contains the enclosing reinforcement, and the inner filament forms hollow channels to accommodate the main longitudinal reinforcement. Using robotic concrete extrusion and eliminating the need for formwork allow for the placement of concrete just where it is needed, resulting in material savings of 40% compared to conventional pouring methods.

Computer-aided design

The design of the White Tower is fully code-generated – it was created without any manual drawing or model. Every detail is scripted parametrically, allowing for easy customization, immersive visualization, simulation of the fabrication process, and compliance with the constraints of the robotic 3D printer. All project data is stored in a digital twin that enables coordination, simulation, evaluation, and construction of the tower without conventional working drawings. The semantic digital model optimizes material consumption and structural performance while integrating high-resolution technical details such as electrical and lighting systems to minimize on-site concrete pouring. Augmented and virtual reality are used extensively in both the design and implementation stages.

Disassembly and reuse

Designed for circularity, the White Tower has detachable connections, thanks to which it can be dismantled after its use in Mulegns and reassembled in a new location. The current plan is for the tower to remain in the Alpine village for five years and then be erected in another, yet undisclosed, location.

Project stakeholders

The White Tower is the outcome of a collaboration between Nova Fundaziun Origen and ETH Zurich, which also involved construction contractors Uffer Group and Zindel United and engineering firm Conzett Bronzini Partner AG. Architects of the tower are Prof. Benjamin Dillenburger and Michael Hansmeyer from the digital building technologies research group at ETH Zurich. The ETH chairs of Robert Flatt (building materials) and Walter Kaufmann (structural engineering) as well as other researchers from the Digital Fabrication National Center of Competence in Research contributed significantly to this project.

Read more about the architects’ motivation and inspiration, the history of the Alpine village of Mulegns, and the background to and development of the collaboration between Origen and ETH Zurich in our “Beton Bauteile 2026” yearbook, which will be published in December 2025.

CONTACT

Nova Fundaziun Origen

Pale Sot 6

7463 Riom/Switzerland

+41 81 637 16 81

ETH Zürich

Rämistrasse 101

8092 Zurich/Switzerland