Experimental and practice-related investigations on anchoring and transmission of forces

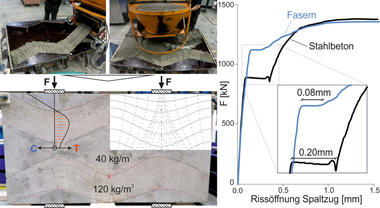

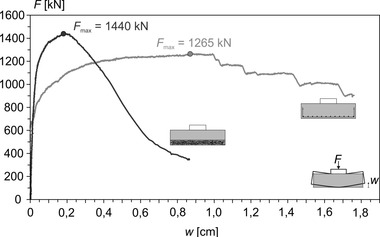

The “steel fiber-reinforced concrete” composite material finds more and more fields of application and is increasingly used for the production of precast concrete elements. For this reason, the engineering structures and the incorporated fastening elements must meet safety-related requirements. Here linear fastening systems such as anchor channels and screws are distinguished as suitable systems for safe and reliable fastening of façade elements to the building shell as well as for the connection of precast concrete elements among each other. In the past, the advantages of steel fiber-reinforced concrete for the fastening systems were not included in the various standards and regulations for lack of systematic investigations. In addition, European approvals do not give any information on whether the addition of steel fibers to the concrete changes the load-bearing behavior of the fastening system. A comparative analysis on the fastening in concrete with and without steel fibers was realized by experimental and practice-related investigations. Within the test scheme conducted, the load-bearing behavior of fastening systems used in steel fiber-reinforced concretes relevant to the precast concrete industry was investigated by means of 96 tests, deriving the advantage of this concrete in the most important fields of application in respect of its load-bearing behavior and the geometric boundary conditions. Here is a potential for optimization that leads to savings in the mentioned fields of application. In this regard, the verifications are provided by pull-out tests and transverse tensile tests on the anchor channels embedded in steel fiber-reinforced concrete using different anchors and edge distances. An optimized load-bearing behavior and an improvement of the minimum geometrical edge distance for practice-related fields of application were also determined in a comparison of the breaking loads and the ductile load-bearing behavior between the structural elements with and without steel fibers.