Economical connection of precast components

The methods used for sealing the joints between precast components used are to this day often outdated, although (demonstrably) more economical technologies for every-day use are available for a long time. The market is often insecure. The company Philipp, as supplier of connection systems, orients itself on the wishes of its customers and the requirements of the market. The demand for more effectivity and economy is here responded to with a wealth of practical knowledge and innovation.

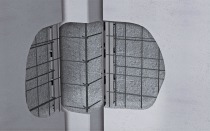

The cost and time advantages gained through precast construction should not be gambled away by the high cost for connecting the components to each other. The technology with flexible rope loops used here has long been state of the art and is part of day-to-day practice of planners and specifiers. This innovative technology, however, could for a long time only be used in combination with a liquid grout whose application involves many time- and material-consuming work steps for creating a tight, layered sealed joint.

The use of a thixotropic mortar is the definitely more economical solution. The plastic consistency of this material obviates the need for sealing and reworking the joints. Formwork boards or joint pressure formwork no longer need to be held in readiness. All that is required is to completely seal one side of the joint with Philipp Thixo Mortar, strike off and level the surface and then fill the other side of the joint and strike and level that surface – nothing could be simpler and more economical.

The consistency of the thixotropic mortar is, when correctly processed, sufficiently liquid to completely fill out all cavities and establish a load-transmitting bond and, at the same time, stiff enough to stand in the joints (no height limitation). The requirements made on the loadbearing capacity of the joint (shear and tensile forces) specified by the planner are clearly met and comply with the specifications of concrete practice. For cases where even higher loads are applied, Philipp has another grouting material available.

The elimination of many unnecessary work steps results into a time advantage of approx. 75% (!) compared to grouting with a flowable mortar.

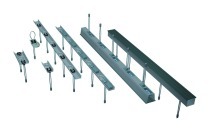

As a sensible extension, Philipp, apart from the successful Power Duo rail, has now added the Power Rail for use with Thixo Mortar and transmittable tensile strengths to its product line.

PHILIPP Gruppe

Lilienthalstr. 7-9

63741 Aschaffenburg/Germany

+49 6021 4027 514

markus.engbert@philipp-gruppe.de

www.philipp-gruppe.de