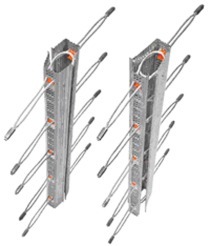

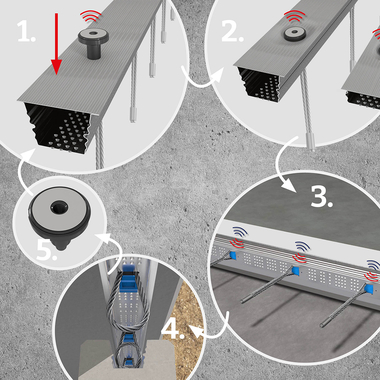

FDS air tube formwork of Pfeifer

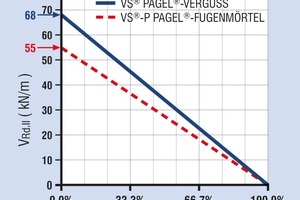

Concerning design resistance, the national technical approvals granted for the wire rope loop systems, that Pfeifer Seil- und Hebetechnik GmbH located in Memmingen calls “VS® System”, do not distinguish between grout and plasticized mortar to be squeezed into the VS® joint.

As it is frequently not possible to fill the joints entirely with the plasticized mortar, the anticipated design resistance is lower in this case (Fig. 1). Competing systems even show larger differences. This is because the viscous material of the plasticized or thixotropic mortar – comparable with the consistency of toothpaste – does not allow to fill edges and voids properly. This means that there will remain unfilled areas being unable to transfer the load entirely.

For this reason, Pfeifer has only acquired the national technical approval for the VS rails until today and has refrained from...