Replacement of the roller bearing annually saves € 68,600

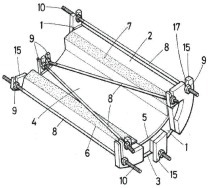

If the automated precast component production does not run “smoothly“ once, a quick action and support of experts is absolutely reasonable. This was the logical response of a manufacturer of precast concrete floor elements, that are manufactured in a sliding mold production process on steel molds at casting beds being about 100 meters long.

The bearings of one of the slipformer machines were damaged several times – over the course of a year, the manufacturer had to suffer 20 downtimes caused by bearing failures. The manufacturing machine is driven by means of a rope traction and two taper...