Leading Asian enterprises opt for the concept of battery molds

Lately, Weckenmann Anlagentechnik GmbH & Co. KG, being a leading German supplier for precast concrete factories, presented a new concept for mobile manufacturing of large-scale precast concrete elements. The first two plants will be delivered in the near future.

There is an urgent need for fast construction of large residential complexes all over the world owing to the rapid population growth and increasing urbanization. Since construction processes are accelerated, with achieving a higher construction quality and safer construction processes that can be planned more reliably, the demand in using precast concrete elements, in particular, as far as floors and walls are concerned, is hence increasing.

In general, the huge temporary building sites for the construction of new residential districts or entire towns do not allow for the erection of conventional, stationary precast concrete plants in the immediate proximity of the building site. While centrally situated precast concrete factories often have the problem of too long transport routes and thus not running efficiently enough. Long routes of transportation, moreover, entail some risks: the goods can be damaged or traffic obstructions may cause a delay in delivery. To some extent, in several countries there is a lack of the necessary infrastructure and transport capacities. Major investments are furthermore required for stationary precast concrete plants, the realization of the same thus often fails due to lacking financial resources or which will not be profitable as there will not be any reliable demand in the long run.

A new concept for mobile molds

This knowledge prompted Weckenmann to think about a new solution in principle. Based on the experience successfully gained over many years in making battery molds, the company developed the concept of mobile molds for the vertical production of flat precast concrete elements in form of a field factory.

The battery mold system designed by Weckenmann as a stationary, vertical mold for the production of precast concrete elements provides the following principal advantages:

Simple and easy-to-use manufacturing process, not requiring particularly skilled and qualified operators.

The final product is a precast concrete wall or floor element with smooth concrete surfaces on both sides, thus ready for painting or wallpapering.

Compact design allowing for high volume output at relatively small floor space requirements.

Insensitive to varying qualities of concrete through highly efficient compaction device. It is therefore possible to use self-compacting concrete, which however is not compulsory. Material costs are reduced in this way, without increasing labor costs.

Energy efficient owing to an optimum utilization of the hydration heat for the curing process and the ability to heat the mold intensely.

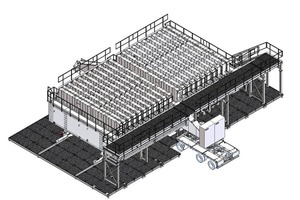

The battery mold is basically composed of the fixed center part, two movable external molds with electro motor drive for ease of operation, several mobile intermediate forms (usually 18 units), vertical side rails and horizontal bottom rails depending on the thickness of the element, which are adjustable in their position according to the different dimensions of the elements, as well as a hydraulic unit and two hydraulic cylinders for closing the mold in a reliable and tight manner. In addition, there are electrical vibrators for concrete compaction integrated in the panels of the mold, being operated by a frequency converter for their continuously variable speed control - this allows for an optimized compaction effort and noise emission. Heating registers for fast concrete curing with a reduced energy input are also arranged in the mold.

Components of the mobile factory

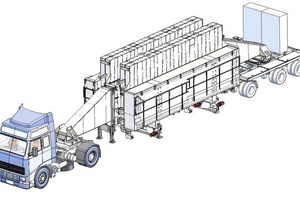

The technical solution provides that a battery mold is built on a special vehicle in form of a semi-trailer, which can be moved by common tractors. The special vehicle, for one thing, serves to transport the heavy central and external molds and, for another thing, can be used on the construction site as central assembly platform being attached to the other working platforms.

These additional working platforms as well as the intermediate forms and other small-scale equipment components will be transported by conventional vehicles from construction site to construction site.

A suitable lifting gear is required in addition to this mobile battery mold system. This equipment, for one thing, is needed for setting up the battery mold, however, will also be used for all other load movements necessary in the ongoing production process, such as the removal of the form, the reinforcement installation and the concrete placement, for example.

If required, the system is complemented by a heating unit fueled by oil or gas, which is providing the battery mold with hot water.

Basic conditions and performance data

A plane and horizontal site with adequate load-bearing capacity is the precondition for setting up the mold system. If need be, individual simple spot footings for supporting the special vehicle and the attached working platform are required.

The special vehicle is brought into position and leveled; then the working platforms are delivered, mounted and adjusted. Afterwards, the remaining components of the battery mold are set up. The battery mold can be put into operation immediately after the connection of the energy supply.

A typical battery mold has 20 compartments measuring 3.5 x 7 m, for instance. A gross production output of 420 m²/day is achieved in this way in single-shift operation. About 10 transports by truck are required per battery mold unit, with one being allotted to the special vehicle. Just a few skilled employees are able to carry out setting up and/or dismantling work within a few days.

First orders from Singapore

Two major construction companies from Singapore with vast experience gained in using precast concrete elements on their own construction sites independently decided to make use of this new technology. In this regard, they carried out comprehensive market and feasibly studies previously, which eventually could confirm the enormous opportunities of this new concept.

The city state situated at the southern tip of the Malay Peninsula with a population of nearly 5.5 million people is virtually predestinated for the mobile battery mold system. On the one hand, the city is shaped by brisk construction activities, with priority on fast construction progress and high productivity, which is called for and promoted by the government. There are hardly any alternatives to the consistent use of precast concrete elements for achieving this objective. On the other hand, in this island with a total area of 712 km² space is a scarce resource for the establishment of industry to manufacture precast elements at a factory.

In the second quarter of 2015, the plants will be put into operation, with most likely giving the local construction industry decisive impetus.