Becoming a leading supplier in the Portuguese market

Founded in 1992, Ilmar is a Portugal-based company specializing in the development, manufacturing, and commercialization of machines and equipment to produce concrete products. ILMAR has become the leading company in the Portuguese market, standing out for its quality, technological innovation, team dedication, and its capacity to deliver turnkey solutions to clients, combining high quality and cutting-edge technology. In this specific project, Ilmar supplied Mendes e Rodrigues Lda with a turnkey solution for a Rapide2000-3 production line.

A New Era in Concrete Production: Technology, Efficiency, and Flexibility

The new production line incorporates the most advanced dosing, vibration, and automation technologies, designed to ensure maximum efficiency, flexibility, and quality in the manufacturing of concrete products. From the batching plant to the final palletizing stage, every element has been carefully engineered to optimize the production process and meet the increasing demands of the market.

Capacity and Flexibility of the Concrete Plants

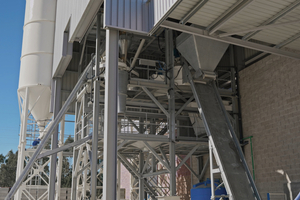

At the beginning of the process are the ASM3600 + ASM800 concrete plants, equipped with a dual system dedicated to each aggregate weighing mixer, ensuring continuous and highly flexible production. This configuration enables simultaneous operation with different compositions and colours, which is essential for producing multicoloured products. The result is higher efficiency in concrete supply, reduced waiting times, and consistent, homogeneous mixes.

The plants are also equipped with moisture probes that allow strict control of the water content in the mix, ensuring consistency and constant quality in every concrete batch. This precise monitoring results in more stable and efficient production, with less material waste.

To guarantee the best conditions and performance, the client required the installation of a high-pressure self-cleaning system that automatically cleans the components after each production cycle. Concrete transport to the press is carried out by an overhead bucket, a solution that ensures a fast and steady flow of material between the plants and the press. This automated system reduces transfer time, supports a continuous and optimized production cadence, and decreases dirt compared with the previous belt-based system.

Performance and Precision with the Rapide 2000-3

The new Rapide 2000-3 machine represents a technological leap in terms of performance and precision. Its harmonic-servo technology, unique in the market, according to the supplier, significantly reduces noise and dust while minimizing tray wear and increasing equipment durability – a solution that has become a standard feature in Ilmar’s high-performance equipment due to its success.

Thanks to its servo vibration system, it is possible to independently adjust vibration speed and amplitude, achieving shorter production cycles, optimized cement consumption, and reduced wear on both equipment and moulds.

The Rapide 2000-3 also includes an automatic table-height adjustment system that adapts instantly whenever the product recipe is changed. This feature ensures perfect adaptation to different geometries and product heights, eliminating manual stops and substantially increasing productivity and dimensional stability.

Another highlight is the fully automatic mould-change system, which allows fast and safe mould replacement in approximately seven minutes. This rapid changeover ensures higher production flexibility, drastically reduces setup times, and maximizes machine availability.

Additionally, the Rapide 2000-3 is equipped with an upgraded hydraulic system composed of two hydraulic pumps and an efficiency-maximization subsystem, which enabled the elimination of accumulators. These features ensure improved overall performance and reduced strain and wear on the pumps. This new hydraulic concept allows smoother, more efficient, and longer-lasting operation, strengthening machine reliability and performance during intensive production cycles.

Efficient Internal Logistics: Finger-Car System and Curing Area

The line is equipped with a high-capacity Finger-Car system capable of transporting 24 production boards measuring 1400x1350x50 mm. This system ensures a stable and smooth cadence between the different production phases, supporting continuous process flow.

The curing area was designed with a storage capacity of up to 5,700 boards, using precast blocks as the base structure – a cost-controlled solution offering high thermal efficiency and ensuring ideal humidity and temperature stability for uniform curing of the products.

The entire curing area is fully computerized, enabling real-time visibility of the curing material and drying time at every point of the curing matrix. All data are available in the machine’s supervision software through a user-friendly interface, where colour coding of each point in the curing matrix evolves over time, allowing operators to intuitively schedule material allocation and removal.

Furthermore, the system can generate a database compatible with any ERP. In this project, the client integrated it into their system, enabling full access to production and curing information both locally and remotely.

Full Automation: Intelligent Palletizing and Sorting

In the final stage of the process, the line features a robotic palletizing system designed to deliver maximum flexibility in handling different products. The system enables automatic palletizing on 1x1 m or 1.2x1 m pallets, easily adapting to varying product dimensions and specific client requirements.

Additionally, the product-sorting system ensures correct routing of parts according to their dimensions, preparing them for dispatch – including options that eliminate the need for transport pallets, optimizing space and reducing logistics costs.

Conclusion

This production line represents the perfect balance between technology, efficiency, and sustainability. The combination of intelligent systems and advanced mechanical solutions not only improves the quality of the final product but also reduces energy and material consumption, establishing itself as a benchmark of innovation in the concrete products sector.

CONTACT

Ilmar

Rua Coração de Jesus 52/70

4590-370 Freamunde

Paços de Ferreira/Portugal

+351 255878488