Automating bending operations: Breuer Stahlhandel invests in automatic, robot-assisted Polybend PBX stirrup bender supplied by EVG

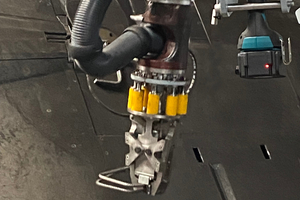

BFT International deputy editor-in-chief, Karla Knitter, visited Breuer Stahlhandel in Goch, North Rhine-Westphalia, to experience the newly installed EVG machine in operation. This automatic PBX bender features an integrated multi-axis robot and is part of a series designed specifically for high repeat and automated subsequent processing.

Long-standing business with modernization in mind

Headquartered in Goch with a second site in Korschenbroich, Breuer Stahlhandel GmbH combines a conventional steel trading business with state-of-the-art manufacturing processes. Founded in 1947 by Ewald Breuer as a concrete plant, the company has evolved over several decades to become a specialized supplier of reinforcing steel, accessories, and custom metal-working products.

Following its integration into Possehl Group, the company continued to grow until Manfred Schenke took over in a management buyout in 2004. He ran the business as a family-owned enterprise for many years. In 2015, Breuer relocated its Willich service center to the current, fully equipped bending shop in Korschenbroich. In 2019, ownership passed to his son, Marcel Schenke, who is further intensifying the company’s ongoing development, particularly in the digital field.

Today, Breuer employs about 50 people. The company processes approximately 30,000 tons of reinforcing steel per year and serves a wide range of customers in the Lower Rhine region and as far afield as Bonn. The combination of conventional steel trading, state-of-the-art manufacturing, an in-house metal-working shop, and streamlined decision-making is considered to be the key driver of corporate success.

Market situation and investment strategy

Despite the current weak demand for reinforcing steel, Breuer deliberately decided to invest in automation at an early stage. The expectation that the market would recover from 2026 onwards was a key factor in this decision. Managing Director Marcel Schenke explains: “We hope that the construction industry will pick up again from mid-2026. We wanted to set the correct course now – at a later point, delivery lead times could become extremely long again.”

The aim of the investment goes beyond simply increasing capacity since Breuer intends to make production more robust and efficient, and less dependent on fluctuating workloads.

From market intelligence to supplier selection

Selection of the new system was based on several years of preliminary planning and obtaining market intelligence. Plant manager Jörg Beermann refers to this process: “As a matter of course, we always keep an eye on EVG’s competitors at trade fairs such as Bauma or Wire, but we haven’t yet found a machine that suits our needs as well as EVG’s.”

Breuer has been using EVG equipment since 1986. The oldest EVG machine in the business has been operating reliably for over 20 years, which was a significant factor in the decision-making process. Beermann puts it in a nutshell: “The machines are expensive, but they are also exceedingly dependable.”

Besides the technical maturity of the systems, collaboration with KMS Kahle was also crucial for the investment decision. This business has been providing maintenance, sales, and commissioning services to Breuer for many years.

Breuer ordered the new PBX machine at the end of June 2025 and commissioned it at the end of October 2025.

Conversion and installation

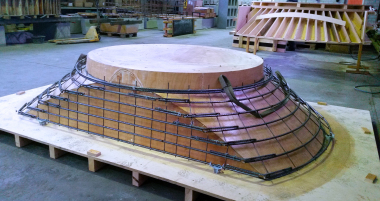

Extensive construction work was required for the installation. The bending shop was restructured, power supply points had to be installed, and additional technical connections and fittings had to be mounted.

Since the PBX machine needed to be installed at a raised level to ensure optimal use of the conveyor, the in-house metal-working shop fabricated a steel frame appropriate for this purpose. The ABB industrial robot that picks, labels, and positions the stirrups was also integrated during the installation process. Integration into the production flow was completed in close collaboration with KMS Kahle.

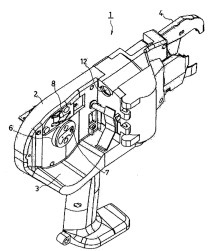

The new system: PBX bending machine with integrated robot-assisted pickup

The newly installed Polybend PBX machine supplied by EVG is part of a series designed specifically for high repeat accuracy and automated subsequent processing. It operates as follows:

in double wire mode up to a diameter of 2 × 12 m

in single wire mode up to 16 mm

cycle times start from 4 seconds (depending on the final stirrup shape)

with a robot payload of 15 kg

The six-axis industrial robot picks the stirrups immediately before cutting, labels them automatically, and arranges them in an orderly pattern on the conveyor belt. This type of positioning is particularly suitable for well-structured subsequent processing while ensuring material flow transparency. Thomas Kügerl, who supervised the commissioning process on behalf of EVG, emphasizes the benefits: “The robot is really proving its worth when producing large quantities – and it doesn’t need any break.”

Production planning with Wire Flow

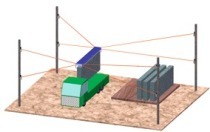

At the heart of the new system is the Wire Flow software, which Breuer uses to digitally map the entire production planning workflow. It

imports reinforcing steel data automatically

defines gripping, labeling, and drop-off points

groups orders intelligently

clearly assigns production batches

visualizes the entire workflow.

Its clearly structured process reduces operator workload, minimizes errors, and stabilizes material flow. Kügerl describes Wire Flow as “easy to use and a great support in the process.”

Initial in-service experience

“After just one week in service, we found that our factory staff responded positively to the new system. They have been very receptive to the new machine, and there was no resistance whatsoever,” says Beermann says.

For Marcel Schenke, the benefit is obvious: “The robot isn’t taking their work away but rather relieving them of monotonous tasks.” In addition, machine availability has improved: “The robot works longer than a standard shift.”

Taking further digitalization steps and envisioning the future

Alongside manufacturing process automation, Breuer is working on additional digitalization projects. One such project is to develop a customer portal that will display the status of orders in real time. The aim is to streamline processes and enhance communication with customers.

Marcel Schenke is also concerned with open exchange within the industry. He stresses that businesses can learn from each other and that innovations should not be held back.

Breuer also defines clear priorities in the field of sustainability, which include installing a photovoltaic system and creating a large wildflower meadow on the company premises, as well as considering how to electrify the truck fleet.

Conclusion

By purchasing the new PBX system, using a multi-axis robot, and implementing Wire Flow, Breuer Stahlhandel took a major step towards automated, digitally supported manufacturing. Combining machine, software and process expertise increases efficiency, stabilizes material flow, and improves working conditions for employees.

CONTACT

Breuer Stahlhandel

Reuterstraße 218

47574 Goch/Germany

+49 2823 107-0

EVG Entwicklungs- und Verwertungs-Gesellschaft m.b.H.

Gustinus-Ambrosi-Straße 1-3

8074 Raaba-Grambach, Graz/Austria

+43 316 4005 0

KMS Kahle Maschinen Service

Molkereistraße 56

30826 Garbsen/Germany

+49 5131 55077