An innovative and sustainable leap in pigment technology

To properly recount the story of SolidFlow, it is necessary to delve into the history of SIOF, to understand the product’s origins and why it was developed in Italy at that time.

SIOF is an Italian company, which recently celebrated 100 years of history. The company was founded in 1923 by three courageous entrepreneurs and has been dedicated to producing, processing and marketing pigments ever since. The name SIOF stands for “Società Italiana Ossidi di Ferro” (Italian Iron Oxides Co.), which highlights the pigments that are the flagship product of the company. With two production sites in Italy, SIOF is still managed by the same three families who started it, and the fourth generation is about to take over.

Mr. Zanella, the president of SIOF and a direct descendant of the founding pioneers, shares the story of the company’s journey into the world of pigments with passion and boldness, typical of Italian entrepreneurship. SIOF stands out by providing exceptional, customized solutions in a market dominated by standardization and global giants. The company’s approach turns pigments into messengers of emotions, bringing colors to life with endless possibilities for imagination and creativity.

Over the past century, SIOF has developed expertise in handling and processing pigments, including the more difficult ones that require careful handling to achieve their full coloring vibrancy.

The word “pigment” originates from the Latin term “pigmentum”, which is derived from the verb “pingere” meaning to color. Pigments are substances that provide color and shade to other materials they mix with. However, they pose a unique challenge due to their insolubility. Pigments are mostly in the form of solid powders, and they need to be dispersed meticulously to mix well with liquids. They are used in many applications, including paints, inks, plastics, and rubber. The dispersion process is crucial as it transforms the solid pigment powder into a fine, stable suspension. This step is essential to ensure the desired color and performance properties of the finished product.

New solution was crafted

Pigment dispersion occurs through a three-step process. Firstly, “wetting” of the pigment takes place where moisture and air are replaced by a liquid or resin. It is followed by “grinding”, where shear forces break down the agglomerates into smaller particles. Lastly, “stabilization” uses dispersing agents to prevent the agglomerates from reuniting, thus ensuring uniformity and stability of the dispersion. This process aims to disintegrate the agglomerates completely to ensure homogeneous distribution of the pigmented particles, which is crucial for the superior quality and performance of the final product.

The process of dispersing pigments is a complex and expensive operation that requires a lot of energy, especially during the grinding stage. It also involves the use of many different chemical additives with complex formulations. Additionally, handling fine powders presents significant risks to the safety of operators and the environment. These challenges become even more difficult in highly automated industrial settings, where the precise handling, transportation, and metering of pigments may be difficult to achieve.

The industry has been facing difficulties and risks associated with the use of powder pigments. To overcome these challenges, concentrated liquid coloring pastes have been adopted. This solution was crafted to improve safety in work environments and precision in the production process. Liquid pastes allow for easy integration of additives into liquid media or resins. This development has been a significant breakthrough as it addresses operational needs, providing greater safety and reliability in industrial applications.

Using liquid coloring pastes may seem like a practical solution, but it is important to note that these pastes can have significant environmental impacts. They are made by mixing pigments with solvents, dispersing chemical compounds, stabilizers and biocides to prevent mold growth. These additives can harm the environment and reduce the sustainability of the product. Additionally, using these pastes comes with operational challenges such as sedimentation. This requires constantly agitated containers and is associated with a high economic burden for packaging and transportation, which is exacerbated by the fact that a significant portion of the material moved consists of water or other liquid substances. This increases costs and carbon footprint.

The pigment industry, along with the paints and coatings sector, has a significant responsibility to innovate with environmental awareness. It is crucial to develop products and processes that aim to significantly reduce the environmental impact. This involves reducing waste generation, eliminating harmful ingredients such as volatile organic compounds (VOCs), reducing the carbon footprint, and adopting materials from renewable or recycled sources.

SIOF started an ambitious initiative

SIOF started an ambitious initiative almost four years ago to develop solid, granular pigments that are safe, manageable and easy to dose. These pigments have a remarkable ability to disperse completely in a liquid with minimal energy, releasing their full coloring potential efficiently. This initiative not only fulfills the need for safety and convenience but also sets the foundation for a more sustainable future in the pigment industry.

SIOF has introduced an innovative method called SolidFlow that redefines sustainability in the pigment industry. Unlike traditional techniques, which use liquid dispersions and energy-intensive drying processes, SolidFlow produces structured granular pigments with a pigment content of over 90 percent. This process reduces energy consumption by more than 80 percent compared to standard methods, making it a remarkable leap in quality. SolidFlow does not require fossil fuels and relies solely on electricity produced by SIOF through photovoltaic systems. This unique product promotes energy conservation and responsible production.

SolidFlow is an innovative process that not only saves energy but also prioritizes sustainability. It achieves this by minimizing the use of additives and choosing eco-friendly options. Additionally, the process eliminates the use of biocides and solvents. As a result, SolidFlow produces highly concentrated pigments and ensures long-term stability, easy transportation, and handling. This approach overcomes critical issues that can arise in the industry. By reducing its environmental footprint, SolidFlow demonstrates SIOF’s commitment to innovative and responsible solutions.

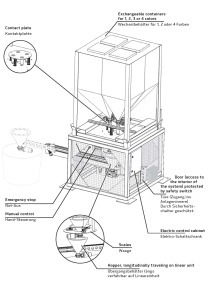

SIOF, a company with extensive expertise in the pigment industry, partnered with an Italian start-up that specializes in applying artificial intelligence to chemical processes. Together, they overcame engineering challenges and created a state-of-the-art industrial plant that is governed by AI and protected by patents. This plant is unparalleled in the world and produces SolidFlow: pigments that flow like a liquid. The innovative product is made in Italy and is a symbol of our commitment to sustainability and future generations.