The fine art of filigree element production

Precast concrete plants are known for rough work and heavy work utensils. But the greatest requirement for a perfect result is accuracy and precision in all work processes. This becomes particularly significant in the production of filigree elements, which must be manufactured with care to minimize damage. It is precisely for this application that B.T. innovation GmbH from Magdeburg has expanded its in-house formwork technology to include the ScrewFrame.

Low wall thickness -

high requirement

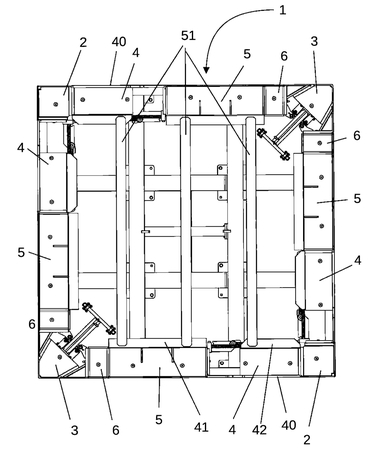

During the growing popularity of building with precast elements, the demands on these very precast concrete elements are increasing. As a result, more demanding elements have to be produced over time, which usually requires precise working methods. A gap in the market for formwork systems for the production of filigree elements was identified, which BT innovation fills with the ScrewFrame. This is designed to simplify the production of such precast elements on tilting tables, in circulation systems and on surface tracks, and can be easily integrated into most workflows. The low profile design of the formwork system, together with the integrated magnets, enables precise operation. The magnets are activated and deactivated individually via a screw system. This can also be done with a cordless screwdriver, which speeds up the process.

The activation of the magnets generates very high adhesive forces, which range between 6,000 and 12,000 N, depending on the length of the shuttering. Such forces guarantee the stability of the system in the concreting process. At the same time, the screw systems can be removed, allowing smoothing devices to be used without any problems. The individual dimensions allow the system to be used for a wide variety of requirements. What is special here, however, is the reusability, which makes the formwork system an efficient and cost-effective asset for any precast concrete plant.

CONTACT

B.T. innovation GmbH

Sudenburger Wuhne 60

39116 Magdeburg/Germany

+49 391 7352-0