Sustainable Precast – New sustainability certification for precast elements

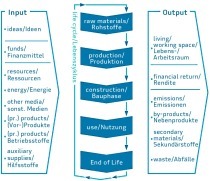

The built environment is the basis for any societal development; it is subject to a constant drive for change and renewal. Due to their long life cycles, buildings and structures have a lasting impact on our society, which is why they should also be designed, built and operated sustainably. The construction products used in them must also play their part in this endeavor. Precast elements in particular meet this requirement to a large extent. They are mainly made from regional raw materials and offer a wide performance range combined with a long service life and good recyclability. However, it is crucial that sustainability aspects be taken into account in the production of precast elements, their raw and input materials, and their installation and assembly.

Besides capturing sustainability aspects in the context of building certification systems such as DGNB, companies are increasingly subject to statutory auditing and reporting requirements with respect to sustainability. Since January 1, 2023, the German Act on Corporate Due Diligence Obligations in Supply Chains (Lieferkettensorgfaltspflichtengesetz) has imposed the duty on large companies to regularly prepare risk assessments related to their sustainability goals within their own business and across their supply chains. If risks are identified, actions to prevent negative impacts on these goals must be taken if necessary. Similarly, at the European level, the Corporate Sustainability Reporting Directive (CSRD) also holds large companies and, in the future, SMEs accountable, requiring them to publish sustainability reports on a regular basis.

Companies that are not directly covered by this legislation should also assume that, as part of a supply chain, they will be required to provide corresponding evidence.

Sustainable Precast is to help precast businesses to focus more strongly on the topic of sustainability and to have their performance in this field assessed and certified independently.