Shaping the future with confidence: Sotubema modernizes its precast production facility with innovative Teka equipment

Sotubema modernized its precast production facility at the Saint Astier site comprehensively by installing a new, low-carbon concrete mixing plant including a high-performance turbine mixer from Teka. This investment strengthens the plant’s technical performance and paves the way to producing a new generation of sophisticated precast components.

French precast producer Sotubema, a member of Carsey Group, has been serving the civil engineering sector since 1955. Today, the business produces a wide range of precast elements, including retaining structures, frameworks, elements for road construction and tunnelling, products for traffic areas, street furniture made from 3D-printed concrete, and – as a new addition to the range – precast substations for the French electricity infrastructure. This wide range is the result of a continuous evolution, which Sotubema is driving together with its sister companies, Chapsol and Carsey 3D, within Carsey Group. A dedicated group engineering office also enables tailored customer solutions and custom designs.

Continuous growth: Development over recent years

The past few years have seen targeted investment in state-of-the-art production equipment. In 2018, Sotubema expanded its capacity by adding a new production facility. This was followed in 2021 by purchasing an automated system for immediate demolding with a hybride press. In 2022, Carsey Group was founded and the Carsey 3D division established, which focuses on industrial-scale concrete printing. In 2023, the range was expanded further to include precast elements for heavy construction. The modernization recently completed at the Saint Astier site continues this development and allows for the manufacture of a new product segment, namely engineered prefabricated energy infrastructure components.

A crucial step: Major order for French electricity infrastructure

Plant modernization was triggered by a new order to produce precast substations. These products require processing of engineered concrete mixes, including self-compacting concrete reinforced with metal fibers. To ensure reliability and reproducibility of these recipes, Sotubema decided to set up a completely new plant, which was commissioned in March 2025. The associated concrete mixing plant followed in September 2025.

Part of the funding of over 3 million euros was provided by the Fonds Vert Territoire d’Industrie managed by French environmental agency, ADEME.

“ADEME co-funding was a crucial lever for us to be able to set up this low-carbon mixing plant,” emphasizes Valki Capron, Deputy Managing Director at Sotubema.

The company is also pursuing the goal of further mitigating the environmental impact of its products. This includes optimizing concrete recipes to permanently reduce both mixing times and carbon footprint.

The new plant: A collaboration between specialist partners

The modernization effort included a completely new production line for precast elements designed for the French energy infrastructure. This setup comprises:

new casting molds for the precast components

lifting equipment, such as overhead cranes, and large-capacity vehicles

a low-carbon concrete mixing plant

infrastructure for integrating electrical components from partner company, Grolleau.

Numerous specialist suppliers were involved in delivering the equipment, including Teka, Walter, Construx, Rocchi, Ballon, Eiffage, and RMPB. The plant is designed to process more than 200 tons of concrete per day and thus meet the requirements of the new product segment in the long term. Several design offices also worked on defining and qualifying the engineered concrete mixes and the design of the infrastructure needed to manufacture the new product range.

Challenging site conditions

The Saint Astier site posed particular construction challenges. Extensive structural strengthening was required because the production facility is located on top of a former limestone quarry. The extremely limited space available posed an additional challenge because the new production facilities and the installations of partner company Grolleau had to be accommodated on-site at the same time. These structural adjustments were not originally planned but could be implemented successfully thanks to the close collaboration of all parties involved in the project.

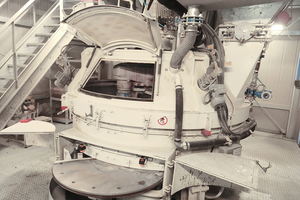

At the heart of the new plant: The Teka THT 1500 turbine mixer

The principal component of the new mixing plant is the THT 1500 high-performance turbine mixer from Teka. For Sotubema, this sourcing decision followed on many years of cooperation – two older-generation mixers have been in reliable use for many years.

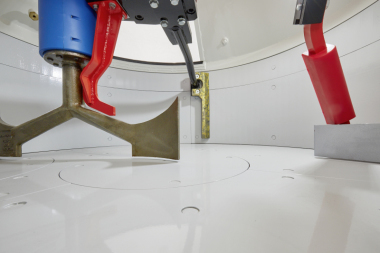

The THT 1500 mixer features a frequency-controlled 45 kW drive motor and achieves a maximum concrete output of 1.0 m³ per mixing cycle. The patented mixing turbine works with a counter-rotating mixing star. This countercurrent principle ensures particularly intensive mixing without damaging the particle structure. The uniform moisture measurement curve confirms the homogeneous water distribution during the mixing process.

The combination of mixing turbine, mixing star, and scraper blades covers the trough floor several times and ensures fast, uniform homogenization. The turbine is carbide-coated, height-adjustable, and self-cleaning. Seals in the hood, folding segments, and inspection hatch prevent water from escaping even under demanding conditions.

The mixer is suitable for:

self-compacting concrete (SCC)

fiber and metal fiber reinforced concrete

face, colored, and polymer concrete mixes

ultra-high-performance concrete (UHPC)

refractory mixes and dry mixes.

One major advantage is its ability to homogeneously mix even smallest batches down to less than 10% of the nominal filling quantity. The exceedingly quick discharge without residues enables short changeover times between products. Reduced wear lowers operating and maintenance costs, and the drive configuration can be optimally adapted to the respective mixing job.

“The mixer is at the very heart of our industrial process. Concrete quality determines the quality of the entire finished component,” Valki Capron stresses. In the associated Teka test station, concrete producers can also conduct their own mixing tests using their materials – yet another benefit that contributes to quality assurance.

Why Sotubema chose Teka once again

For Valki Capron, there was no question that they would choose Teka again. Previously installed mixers had proven to be robust and reliable – a crucial criterion playing in favor of an investment that would last for decades.

Another factor is the locally available service: “Thanks to our Teka subsidiary in France, we can offer an extremely fast service. Our fitters will be on-site immediately whenever they are needed – a crucial factor for our long-term partnership and for ensuring customer satisfaction,” explains Stéphane Sciquot, Teka France subsidiary manager.

Outlook: Capacities for the future

The new mixing plant is not yet running at full capacity since its nominal output exceeds current demand. It was deliberately designed for future growth. The next step is to optimize concrete recipes to further reduce mixing times and carbon footprint. The modernization effort enabled Sotubema to lay the foundation for expanding its product portfolio and ensuring the production of sophisticated precast elements in the long term.

CONTACT

Sotubema

Site de Coubert

Sente de la Forgette

77170 Coubert/France

+33 01 64 42 73 20

Teka Maschinenbau GmbH

In den Seewiesen

67480 Edenkoben/Germany

+49 6323 809-0

info@teka-

maschinenbau.de