Safe processing of modern lightweight concrete blocks

Hesse‘s tallest kindergarten is currently being built in Schmitten-Oberreifenberg (Taunus), right next to the Feldberg. The building is being constructed as an environmentally friendly KfW 40 building using monolithic lightweight concrete. The new, highly heat-insulating „honeycomb blocks“ from KLB Klimaleichtblock (Andernach) are being used for this purpose. This is an opportunity for the well-known masonry supplier to demonstrate the correct processing of lightweight concrete blocks in practice using the shell construction – from laying the base layer to the finished wall.

Millimeter precision

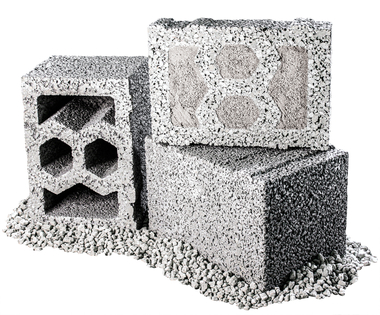

Flat blocks are masonry blocks that are ground to millimeter precision during manufacture. Due to their high dimensional accuracy, they enable masonry to be erected with around 85% less jointing. Masonry with thin-bed joints is now the standard method of construction. This significantly optimizes thermal insulation. At KLB Klimaleichtblock (Andernach), all bricks in the KLB flat brick range are manufactured in the respective factory with such precision or ground on the contact surface that the height tolerances of the bricks are no more than one millimeter. This also applies to the new, highly heat-insulating „KLB honeycomb block.“ With its bionically inspired honeycomb geometry and insulation filling made of pure mineral foam, it achieves outstanding values in the areas of thermal insulation, fire protection, and sound insulation. In addition, according to the current Environmental Product Declaration (EPD) by Kiwa Ecobility Experts (Berlin)it an around, has environmental impact that isbetter than comparable filled lightweight concrete blocks. For these reasons, it is currently being used in the shell construction of „Hesse‘s tallest kindergarten“ in Schmitten-Oberreifenberg on the Großer Feldberg, which will accommodate a total of 72 children in four groups in accordance with the KfW 40 standard (40%).

The laying of honeycomb blocks, which are mainly made of volcanic pumice, is essentially no different from that of other flat-ground lightweight concrete blocks. They can also be laid using the standard tongue-and-groove system and can be quickly processed using the thin-bed method. Manufacturer KLB Klimaleichtblock took this opportunity to once again document the correct processing of planed blocks using the thin-bed method step by step for professionals on site.

Successful in use

During the construction of the kindergarten in Schmitten-Oberreifenberg, the contracted construction company Albert Weil AG (Limburg) used the new „KLB honeycomb block“ for the first time to build the highly insulated exterior walls – with noticeable success: „Our company pays close attention to quality. In my opinion, the new honeycomb block is very good. It is the ideal weight and is easy to work with on the construction site,“ explains Ralf Haas, the foreman responsible at Albert Weil AG. He also sees it as a particular advantage that the highly heat-insulating honeycomb blocks can be sawn without the mineral foam filling falling out or trickling down.

Like all standard lightweight concrete blocks, honeycomb blocks can be processed using the thin-bed method. Therefore, the top of the wall must also be protected with a covering membrane made of bitumen or a similar water-repellent material to prevent moisture from penetrating and damaging the filling. In addition, the new honeycomb blocks have a top with a cover. Because the covered side is always on top, the masonry is additionally protected from mechanical damage.

Construction professionals can find all relevant data on the new „KLB honeycomb block,“ including processing instructions, in the manufacturer‘s brochure of the same name.

CONTACT

KLB Klimaleichtblock GmbH

Lohmannstraße 31

56626 Andernach/Germany

Andreas Krechting

+49 2632 2577-0