Revolutionizing precast construction in Singapore: Inauguration of the HL-Sunway Prefab Hub

In the bustling city state of Singapore, the construction industry has reached a significant milestone with the inauguration of the HL-Sunway Prefab Hub in the summer of 2023. This state-of-the-art prefabrication facility supplied by Progress Group represents a groundbreaking collaboration between Hong Leong Asia and Malaysia’s Sunway Construction Group. This hub aims to revolutionize the construction sector in Singapore by boosting productivity, enhancing workplace safety, and accelerating the production of precast building components.

The HL-Sunway Prefab Hub is no ordinary facility: Its impressive annual production capacity of up to 100,000 cubic meters of precast components provides the potential to support the construction of approximately 17 apartment blocks – a significant benefit to Singapore’s ongoing build-to-order (BTO) projects. This hub is the sixth and largest planned for Singapore; it is designed to produce a comprehensive range of components to be used in residential projects across the island.

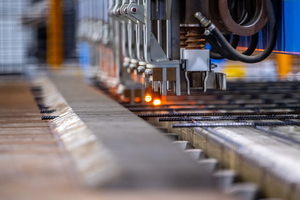

Automation at its core

Automation is at the heart of this cutting-edge plant. The HL-Sunway Prefab Hub incorporates advanced features such as an automated mesh production plant for reinforced concrete production, an M-System Evolution mesh welding plant including bending features, and a magnetic traverse for transport and logistics. The plant is equipped with the largest automated storage and retrieval system (ASRS) in Singapore, including inside and outside storage as well as fully automated pallet stackers and central shifters. The hub uses a robotic warehousing system for the efficient storage and retrieval of the precast elements. Including 26 production beds and two automated precast production systems comprising Form Master shuttering and deshuttering robots, concrete spreaders, pallet cleaning devices, and compacting and turning equipment, the facility is poised to achieve an impressive 80% increase in overall productivity when operating at full capacity. Additionally, the hub boasts 54 loading bays for the seamless discharge of goods, enabling it to supply 100,000 cubic meters of precast elements annually — enough to build about 2,500 dwelling units.

Singapore’s Minister for National Development, Desmond Lee, emphasized the significance of localizing precast production capabilities: “This move toward automation and innovation is expected to create job opportunities for Singaporeans, allowing them to transition from physically demanding roles to higher-skilled jobs with better pay.”

Sustainable practices for a greener future

The hub is committed to reducing its carbon footprint and promoting environmental sustainability. It has implemented energy-saving practices, including wastewater recycling, and is equipped with over 1,700 solar panels to harness renewable energy. These initiatives reflect a commitment to environmental stewardship and align with Singapore’s broader goals of reducing carbon emissions.

Standardization for efficiency

One of the most notable features of the HL-Sunway Prefab Hub is its focus on standardization. The facility offers standardized dimensions and connection details for precast components. This standardization translates into increased efficiency, reduced downtime, and lower production costs for the construction industry, and it is one of the most important features provided by automated production.

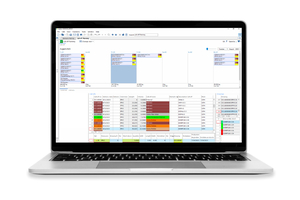

Software integration

The integration of advanced software systems has been a substantial part of the hub’s operations. For the facility, R3 and Sunway implemented robotic technology with CAD-CAM capabilities, including BIM to PXML from Progress Group supported by Tekla and Trimble. This integration enhances the precision and efficiency of the precast manufacturing process and makes it easy to extract data from the system by generating a daily production report, finance report and quantities for billing. The industry-specific erpbos ERP system from Progress Group provides a dependable overview of all business processes. The project life cycle is constantly updated, allowing to make decisions in real time and keep costs and time under control. The openness of the solutions makes it possible to integrate the system with existing ones. To operate these systems effectively, R3 and Sunway have invested in training its workforce. BIM modelers, CAD-CAM specialists, technicians, and operators received training to operate software, robots, and machinery, resulting in a highly skilled and knowledgeable workforce.

Collaboration with Progress Group

The collaboration with Progress Group, a key partner in the development of the HL-Sunway Prefab Hub, has been instrumental in the project’s success. Progress Group served as a turnkey solution specialist, working closely with Hong Leong Asia and Sunway from the tender stage to the opening ceremony. The collaboration extended across various phases, including sales, project management, installation, testing, commissioning, and operation. Despite differences in time zones, the collaboration has been marked by a positive relationship and effective communication. Progress Group’s presence in Kuala Lumpur further facilitated timely interactions with customers, enabling responsive solutions to challenges encountered during the project.

“It was a fantastic experience working with Progress Group and its local partner in Singapore. Their effectiveness in addressing issues during machinery installation and commissioning, along with their quick response and problem-solving skills, is certainly commendable,” says Kwong Tzyy En from HL-Sunway Prefab Hub and adds: “We believe such experience can greatly contribute to the success of projects and organizations.”

The collaboration behind the hub

The development of the HL-Sunway Prefab Hub is the result of a fruitful collaboration between two prominent entities, Hong Leong Asia and Sunway Construction Group Berhad. Hong Leong Asia’s wholly owned subsidiary, HL Building Materials Pte Ltd, holds a 51% equity stake, while Sunway Concrete holds 49% in the joint venture. Stephen Ho Kiam Kong, CEO of Hong Leong Asia, and Tan Sri Dato’ (Dr) Chew Chee Kin, President of Sunway Group, expressed their commitment to integrating construction processes with a lower carbon footprint and achieving high throughput and productivity. Their shared vision emphasizes sustainability and innovation in the building environment.

Tan Sri Dato’ (Dr) Chew Chee Kin, President of Sunway Group, said: “Sunway and Hong Leong Asia share a common vision and aspiration in our journey towards innovation, efficiency, and sustainable development for the built environment. This hub represents the seamless integration of cutting-edge technology, intelligent design, and the expertise of our skilled workforce. It signifies a paradigm shift in the built environment sector today by harnessing the use of prefabrication and modular construction methods.”

CONTACT

HL-Sunway Prefab Hub

10 Punggol Barat Lane

Singapur 797359

EBAWE Anlagentechnik GmbH

Dübener Landstraße 58

04838 Eilenburg/Germany

+49 3423 6650

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979100

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159