Resource-efficient tunnel elements produced in a carbon-reduced lightweight design using AI-based manufacturing processes

Enormous material consumption and associated carbon emissions are still the rule rather than the exception in tunnelling. The RTTS research project funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) specifically addresses this situation. Under the head responsibility of Ed. Züblin AG, an interdisciplinary consortium is developing resource-efficient, climate-optimized tunnel segment and mortar systems based on new concrete technology approaches, digital manufacturing processes, and AI-assisted assessment of materials. This project aims to create an innovative tunnel support system that is sustainable, durable, and commercially viable.

Infrastructure consumes enormous amounts of materials

The infrastructure sector consumes enormous quantities of materials owing to complex soil-structure interactions and demanding durability requirements for structures. Production of such materials is associated with significant carbon emissions and resource consumption. Construction of the Gotthard Base Tunnel in Switzerland, for instance, resulted in approximately 4.1 million tons of carbon emissions, equivalent to about 27,000 tons of CO2e per kilometer of tunnel [1]. Similar figures are available for the Brenner Base Tunnel, for which total emissions of 2.1 million tons of CO2e were reported [2]. Additionally, enormous amounts of resources are consumed, such as for binders and aggregates. More specifically, tunnelling produces massive amounts of excavated rock, most of which has been landfilled to date. In Austria, for example, approximately 55% of total waste can be attributed to such excavated materials [3].

Huge potential for driving down carbon emissions

Tunnel elements typically consist of precast concrete lining segments that form rings to create the tunnel tube. The annular gap between the surrounding rock and the segments is backfilled with a special type of grout, the production of which also results in high carbon emissions. Worldwide, tunnelling still relies on lining segments with exceedingly high carbon emissions of approximately 700-1,000 kg CO₂/m³ based on Portland cement concrete. However, by using new binder systems, optimizing concrete technology, and switching to fiber-reinforced concrete, the authors estimate that the carbon footprint of segment production could be reduced by approximately 60% compared to the previous standard. Further savings potentials lie in reducing concrete consumption through innovative lightweight design solutions [4]. However, one of the major challenges is to reliably implement such solutions in practice.

The RTTS research project

Funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK), the RTTS research project is developing solutions that specifically address these issues while evaluating the potential risks and benefits of related decisions in design and production.

This project aims to develop a resource- and climate-optimized concrete tunnel support system based on innovative, digitally controlled manufacturing processes.

The research consortium includes companies Ed. Züblin AG, Master Builders Solutions Deutschland GmbH, and Dyckerhoff GmbH, as well as the Research Association for Tunnels and Traffic Facilities (STUVA e. V.), and the Institute of Building Materials Science at Leibniz University Hannover (see Fig. 2). Ed. Züblin AG coordinates the consortium.

Focusing on producing resource-efficient, carbon-reduced tunnel segments and annular gap backfill mortar

Work in the RTTS project consortium focuses on producing resource-efficient, carbon-reduced tunnel segments and mortars for annular gap backfilling (see Fig. 3)

for which innovative climate-optimized concretes and mortars are used. Using innovative digital, fully automated control engineering in concrete and mortar production allows for a significantly higher proportion of excavated tunnel materials to be recycled and reused for concrete production to reduce resource consumption significantly

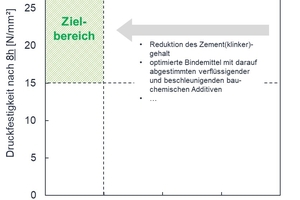

in which the cement (clinker) content and thus the carbon footprint of the concrete is reduced to a minimum using optimized binders, specially adjusted liquefying and accelerating additives, and automated mix control concepts

in the development of which innovative simulation methods are applied that are directly linked to subsequent production via sensor data and optimized for maximum safety, minimized environmental impact, and outstanding cost effectiveness, thus ensuring significantly improved, data-proven sustainability characteristics,

whose production, simulation, and sensor data are stored in a digital twin, creating preconditions for a service life of at least 100 years, easy maintenance, and complete, carbon-positive recycling at the end of the use phase.

Concrete technology approaches

In concrete technology, this research is investigating various approaches to developing climate-optimized concretes. At the binder level, for instance, calcium sulfoaluminate (CSA) cements [6] and granulometrically optimized ternary binders consisting of clinker, granulated blast furnace slag, and limestone powder are used [7, 8]. These binder recipes are complemented by specially designed accelerating additives [9]. This approach made it possible to reduce the binders’ carbon footprint by up to 60% compared to the reference scenario (CEM I), while retaining similar technical characteristics, including high early strength and sufficient carbonation resistance.

Another goal is to maximize the substitution rate of virgin aggregates by excavated tunnel materials while reducing the carbon footprint in developing concrete mix designs as far as possible. Because such materials generally exhibit large fluctuations in their properties that prevent their widespread reuse, the project also focuses on developing sensor-based process control methods for concrete production and use. Sensor-based, AI-assisted methods and algorithms are used to determine the properties of excavated tunnel materials through imaging [10, 11]. This allows data to be gathered for an assessment system that uses prediction models to enable targeted control for automated concrete production. All data is then fed into a digital twin.

The consortium’s broad range of partners from industry and academia makes it possible to address and consider all points referred to above as part of the project, which should allow for direct, targeted, practical, and commercially viable implementation of project findings.

The RTTS project consortium would like to thank the Federal Ministry of Economics and Climate Protection (BMWK) for funding the research project “Development of a resource-efficient tunnel elements based on an AI-based manufacturing process in CO2-reduced lightweight construction”.

CONTACT

Leibniz Universität Hannover

Institute of Building Materials Science

Dr.-Ing. Tobias Schack & Dr.-Ing. Max Coenen

Appelstraße 9a

30167 Hannover/Germany