New ice and hot water plant tempers fresh concrete efficiently

Climate protection and increasing resource scarcity are just two challenges that the construction industry must face in the future. It is therefore all the more important to produce concrete as durable and long-lasting as possible. To achieve the necessary quality, the material must cure thoroughly. Otherwise, cracks can still form months later, causing massive damage to the structure and demanding extensive repair work. However, very high or low ambient temperatures, which are becoming more frequent and prolonged even in Europe’s and North America’s moderate regions, make temperature-controlled concrete production increasingly difficult. This results in exploding energy costs for concrete cooling and heating as well as rising emission values.

The new CombiWater by KTI-Plersch Kältetechnik GmbH, which was developed specifically for concrete production, now offers a solution. The flexible and energy-efficient heat pump produces iced water in summer and hot water in winter. The recirculation mode keeps the once tempered water in the insulated tank efficiently cold or warm even during downtimes.

Plug-and-play thanks to turnkey installation

“When building infrastructure projects such as airports, but also dams, tunnels and bridges, you need massive components made of concrete,” knows Michael Walleter, sales manager at KTI-Plersch Kältetechnik GmbH. “These components need a relatively long time to cure thoroughly.” However, fluctuating, very high or low ambient temperatures during this period make controlled, high-quality concrete production impossible. Temperature differences within the component, for example, cause individual areas to harden more or less rapidly.This results in cracks that, in the worst case, might lead to the demolition of the component. Moreover, temperatures that are too cold cause the still moist concrete to freeze, which also severely impairs the stability and durability of the finished component.

A conventional concrete cooling system, such as that used in desert regions, usually uses flake ice as a chiller. Although very low concrete temperatures can be achieved in this way, they are not even needed for less complex applications in more temperate latitudes. For small and medium-sized businesses in particular, it is therefore worthwhile to resort to significantly more energy-efficient cooling with ice water. In the area of concrete heating for cold ambient temperatures, the demand for alternative and low-emission fuels is also growing. “Climate protection and corresponding guidelines are playing an increasingly important role in the construction industry,” confirms Walleter. “In addition, fluctuating climatic conditions are becoming more frequent, with record summers and winters even in Central Europe. Both are causing more and more problems for concrete production in this region.”

High quality concrete produced 365 days a year

The new CombiWater from KTI-Plersch is based on the principle of a heat pump that can run in both heating and cooling mode as required. In summer, the system produces the iced water (< 1 °C) needed for concrete cooling. As soon as ambient temperatures drop, the system can simply be switched to heating hot water. “With the CombiWater, you literally kill two birds with one stone and save the acquisition as well as maintenance costs for two separate systems for cooling and heating,” explains Walleter. “That’s why it’s particularly well suited for use in more temperate latitudes, where cold winters alternate with hot summers.”

The CombiWater can switch between two operating modes for both ice and hot water production: In open loop mode, it cools with an output of 61 kW and heats with 92 kW. Given a temperature difference of 21 °C to < 1 °C, this corresponds to about 2.5 m³/h of water in cooling mode and about 1.8 m³/h of water from 10 °C to 55 °C in heating mode. If the insulated tank is full and tempered water is not currently required, then the system effectively keeps the cooled-down or heated water at the desired temperature in recirculation mode. “This function is particularly useful when concrete production is not currently taking place,” explains Walleter.

High concrete quality even in remote or cramped locations

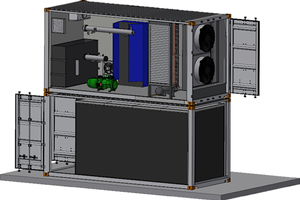

Like most plants from KTI-Plersch, the CombiWater is installed in a shipping container and is delivered ready for use. It is thus very mobile and can be transported quickly and easily to new, and even more remote, locations. Thanks to the plug-and-play solution, installation time is kept to a minimum, saving manpower and resources on site. As there is no need for chimney installation, only the water and power supplies need to be connected. “Due to its compact container design, the ice and hot water plant is also well suited for high-quality concrete production on inner-city construction sites, where space is often at a premium,” Walleter adds.