Innovation, a growth driver for French manufacturer

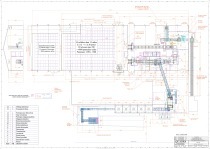

As an expert in automated processes and vibration systems, Quadra designs and builds turnkey production machines for manufacturing a wide range of concrete products such as blocks, pavers, slabs, curbs, fences, and more. Its latest-generation, innovative, and versatile equipment is sold both in France and worldwide.

At the last Bauma, the French manufacturer presented its latest technological breakthroughs.

More Efficient and Energy-Saving Presses

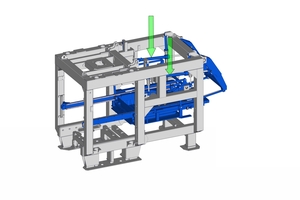

Among the major innovations, Quadra unveiled two significant upgrades to its block machine. The first concerns the electrical feed box, which now replaces the former hydraulic cylinder system. This evolution, thanks to the use of a servomotor and a chain drive system instead of articulated arms, allows for on-demand operation rather than continuous movement. The result is an estimated 15% energy saving, not more maintenance required, an accurate feed box positioning and a movement consistence. This innovation has been patented.

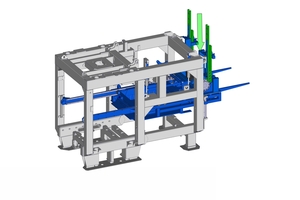

The second major improvement consists in replacing the hydraulic aggregate by a servo-controlled unit. A dedicated servo pump adjusts the pressure and debit to the need in the cycle for each movement. Proportional valves are then useless and are replaced by on/off valves. These parts are much more reliable, a PLC is synchronising all the components, the architecture is more simple thus reliable and less affected by the consequences of oil pollution. The measured energy saving is by 20% compared to the previous generation.

Connected Services for Operators

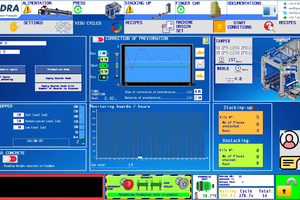

Quadra’s innovation also extends beyond mechanics, integrating smart solutions to enhance machine operation, training, and maintenance. For instance, a Chat Bot has been developed to assist operators with real-time diagnostics and troubleshooting. This is complemented by an online machine learning module that enables automatic correction of production parameters.

In addition, a real-time vibration monitoring system has been implemented. It provides alerts at two thresholds:

Level 1: a warning message appears on the main control panel.

Level 2: the press automatically adjusts its settings if the defect occurs twice in a row, thereby preventing potential damage.

Another evolution is Quadra 4.0 „enhanced“ customer service which allows them to have real-time access to their equipment and all production parameters. Whether remotely or on-site, they can view and respond to the current performance of their block machine, analyse the causes of downtime in details, and compare their production parameters with different moulds. This system greatly facilitates exchanges between operators and technicians, enabling rapid response to operator requests and effective assistance during adjustment or troubleshooting operations.

Customers may also have access to an online collaborative platform. User-friendly, interactive and intuitive, it enables them to transmit their requests quickly and easily (information requests, incident reports and quotation requests). They can also access their spare parts catalogue, download technical documentation for their equipment, as well as operating instructions and animated tutorials.

At last, to facilitate on-site intervention, Quadra now offers WiFi-connected touchscreen tablets. These tablets mirror the main control screen, allowing operators to adjust settings directly in front of the machine, enhancing both efficiency and precision.

100% Quadra Expertise

All these innovations are the result of the work carried out by Quadra’s teams based in France. Divided into specialized design offices - mechanical, electrical, hydraulic, automation, and robotics – around sixty engineers and technicians collaborate to develop ever-more-efficient solutions focused on productivity, new construction systems, energy savings, and operational ease.

CONTACT

Quadra

40, route de Findrol

74130 Contamine-sur-Arve/France

+33 4 50 03 92 21