Gradual modernization process of the

Creabeton facility in the Swiss Lyss

The gradual modernization of concrete block production line 1 of Creabeton Matériaux in the Swiss town of Lyss has been completed successfully, i.e. the entire dry side of the interlocking paving block making machine. Disassembly of the old plant as well as assembly and commissioning of the new Quadra equipment took place from December 2022 to March 2023.

It all started with the foundation of a concrete plant by Johann Bangerter in Lyss in 1876. Today, the Creabeton Matériaux AG based in Lyss near Bern together with the other three production sites in Granges-près-Marnand, Müntschemier and Einigen is strongly anchored in the regions of Central Plateau and Western Switzerland. The company looks back on a long tradition in the production of concrete products of high quality: Since 1876, gravel had been quarried by the Bangerter company at the Seeland-based location, and they had been manufacturing concrete products. In 2000, they merged with Kanderkies AG, Tribeton AG and BTR AG to become Creabeton Matériaux AG. The Desmeules Frères SA, Granges-près-Marnand (founded in 1901) joined in in 2007.

The Creabeton Matériaux AG is a full-range supplier in the market of concrete products and has a workforce of about 260 people across the four production sites.

Paulo da Silva, foreman of the interlocking paving block factory 1 & finishing line at Creabeton, states: „Together with the group, we consider us as the market leader in Switzerland for concrete goods and many more products in the field of garden and landscape construction. Our strengths are the high amount of in-house production, the full range of products and the high number of products that are available immediately ex stock.“

New production equipment by Quadra

Quite recently, the gradual modernization of the Lyss concrete block production line 1 was completed with success, i.e. the entire dry side of the interlocking paving block making machine with an investment volume of approx. 1.5 million euros. The project approval took place in September 2020, the last contract negotiations were in September 2021 and the contract was awarded in October 2021. The actual disassembly of old plant as well as assembly and commissioning of the new machine took place from December 2022 to March 2023.

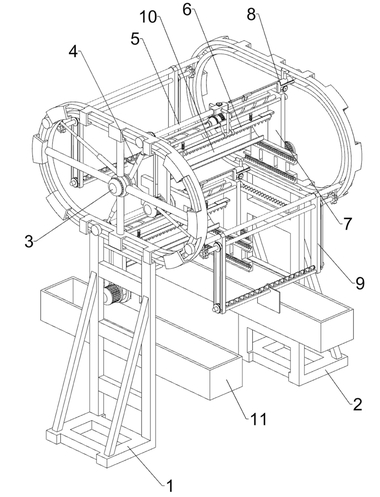

Paulo da Silva reports: „In 2017, we started with our modernization offensive in the form of a new pallet buffer system featuring a capacity of 5,000 boards. At the same time, the old Henke board crane delivered in 1998 was decommissioned. Afterwards, further modernization steps followed almost every year, e.g. a new transfer table in 2019. Finally, the decision was taken in favor of the French equipment manufacture Quadra because of our high standards in terms of quality, prices and performance as well as because of our positive experiences with the equipment components installed already. Our brief was to pack 100 different product formats and, in some cases, to reformat them, all within specified cycle times.. Now, as the Drying machine made by Quadra as well as all other equipment components, such as the palletizing unit with two Kuka KR1000 und Kuka KR700PA robots, for example, are running smoothly, we are proud to say that all extensive modernization measures have been completed with success and our requirements and expectations have absolutely been fulfilled.“

Yannik Ancrenaz, General Manager of Quadra, the French machinery and equipment specialist, commented: „Recently, there are a lot of pleasant news of Quadra to be announced. We have, for example, brought a new concept of the vibrating press with immediate demolding to the market, characterized by the fact that demolding of this equipment operates in two different modes – either by turning the mold over or by raising the mold. Hence, this special vibrating press has the capability of manufacturing a wide range of products. The production is running fully automatically with particularly optimized industrial production rates.

Another highlight, worth mentioning, is the modernization of the concrete goods manufacturing plant of the Alsace-based Heinrich & Block company at their Steinbourg and Wittenheim facilities using exactly this vibrating press. I mention this because you too have already visited this interesting and innovative company personally, with reporting on them comprehensively in the BFT magazine.“

The General Manager of Quadra continued: „But now back to our current engagement at Creabeton: we have supplied the entire dry side including pallet crane, transfer table, cube crane, lifting- and two lowering ladders. The collaboration with the team of Creabeton was really excellent. As a result, in less than two months, from the actual installation in week 3 to 6/2023 and the test runs in week 7 to 8/2023 through to the start of production in the ninth calendar week of 2023, we managed everything perfectly.“

According to the parties involved in the project, it was especially challenging to take into account the working steps of all equipment components included in the process chain.

Future plans

When asked about further milestones, Paulo da Silva replied: „In the near term, the replacement of the board-based block machine is still pending as the last stage of the modification. The current market situation, however, does not yet allow to operate at full capacity, but investments are planned in the field of pavements and concrete mixing plants in the medium- and long-term. In addition, it is intended to improve the support in German language. And last but not least, we at Creabeton Matériaux want to make an even stronger commitment regarding the environment and sustainability, e.g. by using more recycled-aggregate concrete of types RC and RCM.“

CONTACT

Creabeton Matériaux AG

Busswilstrasse 44

3250 Lyss BE/Switzerland

+41 032 387 87 87

Quadra

40, route de Findrol

74130 Contamine-sur-Arve/France

+33 45033-9221