Extensive investments, craftsmanship, and highly motivated teams

Since 1909 Mattig & Lindner GmbH has developed into one of the largest medium-sized construction companies in the German federal state of Brandenburg. In addition to the production of precast concrete elements (floors, walls, structural precast elements and special elements), the company – located in Lusatia, the border region between the federal states of Brandenburg and Saxony, and Poland – is active in building construction, hall construction and reinforcement construction.

It all began on July 1, 1909: Max Mattig, great-grandfather of the current managing directors, founded a bricklaying business in the city of Forst; his son-in-law, Master Builder Oswin Lindner, became a partner. Right from the start, the company was involved in the construction of many residential buildings in Forst.

Since the reprivatization of the Company on July 1, 1990, the divisions of turnkey construction, hall construction, precast concrete production and delivery of ready-mixed concrete enable a high level of service complexity. In-house industrial research ensures that the work is carried out to the highest standards. Extensive investments, craftsmanship, highly motivated teams and sensitive management quickly restored Mattig & Lindner GmbH to its position as a key company in the region.

Present and future

Today, Mattig & Lindner GmbH is one of the largest medium-sized construction companies in Brandenburg and, with the knowledge and capabilities of a large company, takes on construction projects of any size and complexity. Its medium-sized structure allows it to react quickly and flexibly to constantly changing market conditions. As a complex service provider, M&L is active as a project developer and general contractor in the following areas:

Building construction

Hall construction (turnkey construction of industrial and commercial properties throughout Germany)

Precast concrete production (floors, walls, structural precast elements and special elements

Reinforced concrete construction.

The market for precast concrete elements in the federal states of Berlin and Brandenburg is currently characterized by sustained growth, especially in the areas of residential and commercial construction. The rising demand for affordable housing and the need for rapid construction methods favor the use of precast concrete elements.

In the short to medium term, investments in measures for manufacture of environmentally friendly products (CO2-reduced concretes) are on the agenda. Another topic for the future is progressing digitalization. In addition, there are regular plant modernization projects also worth mention here: apart from the Sonocrete ultrasonic technology described below, the recently commissioned concrete production plant of Sommer Precast Technology.

New high-performance ultrasonic system

The production of climate-friendly concrete with reduced clinker content is also becoming increasingly important in Berlin and Brandenburg. Mattig & Lindner has therefore set itself the ambitious goal of reducing CO₂ emissions in precast concrete production by 25%—through the use of clinker-reduced cements and the extensive elimination of heat treatment and chemical accelerators. A central component of this strategy is the introduction of Sonocrete ultrasonic technology. As part of the joint research project “Ultrasound-assisted concrete production” (BMBF funding measure KMU-innovativ, 2021–2023), the effectiveness of the technology has been proven several times under real production conditions. The activation of a cement-filler slurry using high-performance ultrasound enables targeted acceleration of the hydration processes – and thus significantly increased early strengths, even with reduced clinker contents.

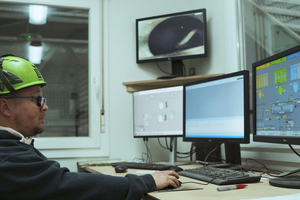

Based on the positive results of the trial campaigns, one of the first Sonocrete plants to be used industrially was installed at the Forst site at the end of 2024. The commissioning initially presented the joint project team with a number of challenges – among other things, only one silo was connected to the plant, although two silos would have been ideal after the process changeover to a cement-filler mixture. Integration into the higher-level control system also required additional adjustments. Nevertheless, all obstacles were successfully overcome thanks to the close cooperation between Mattig & Lindner and Sonocrete.

With the new plant, Mattig & Lindner is setting a technological milestone in the direction of sustainable concrete production and demonstrating how innovative strength and practical relevance can work together.

From plant testing to actual operation

After completion of the trial phase, real-world operation confirmed that the desired reduction in clinker content can be reliably achieved. Sonocrete technology not only enables stable processes, but also leads to significantly increased early strength—a decisive advantage for industrial precast manufacturers.

The successful transition from pilot operation to continuous production lays the foundation for further innovation. Just a few days ago, a new chapter in the collaboration began: the first trials of preparing cement-filler slurry with recycled water were promising. The integration of a closed water cycle could lead to additional resource savings and further increase ecological potential in the future.

The results so far clearly show that with the systematic introduction of ultrasonic technology, modern mixing processes, and digital control concepts, Mattig & Lindner is making an important contribution to more sustainable precast concrete production — and positioning itself as a pioneer in the region.

Satisfied statements from those involved in the project

Michael Lindner, Managing Director of Mattig & Lindner GmbH, was delighted: “Our collaboration with Sonocrete has now been going on for five years and is characterized by mutual appreciation and support. This plant is truly unique and has great potential for the future. Our goal—a 25% reduction in CO2 emissions—has already been achieved thanks to the conversion. The next milestone we are aiming for is a 10% reduction in the total amount of cement used.”

Dr. Nora Baum, CFO at Sonocrete, explained: “With commissioning of the Sonocrete plant in 2024, Mattig & Lindner in Forst has set an important milestone for climate-friendly concrete production. This innovative technology is based on the use of high-performance ultrasound to activate a fine-grained cement slurry. This allows the reaction processes in the concrete to be specifically accelerated and CO₂ emissions to be reduced by up to 30 % – without compromising on quality or performance. The first construction projects in Berlin and Brandenburg are already benefiting from this more sustainable concrete. Mattig & Lindner is thus actively contributing to making the construction industry in the region fit for the future and to supporting the industry’s climate targets. With its combination of state-of-the-art technology, regional value creation, and active responsibility, the company is positioning itself as a pioneer for a new generation of concrete – innovative, resource-efficient and high-performance at the same time. Mattig & Lindner is an important practical partner for Sonocrete – all prototypes were first tested here, and large development projects were tackled jointly.

CONTACT

Mattig & Lindner GmbH

C.-A.-Groeschke-Str. 15

03149 Forst/Lausitz

+ 49 3562 9703-0

Sonocrete GmbH

Hermann-Löns-Straße 20

03050 Cottbus/Germany

+49 355 54788170