Efficient dosing technology reimagined – the MODS24 in modern use

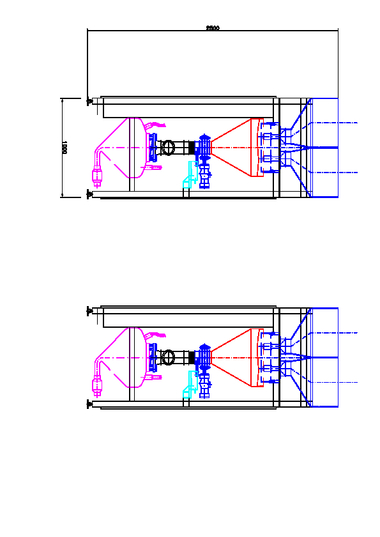

The MODS24 mobile dosing system has established itself in practice as a real advantage package in paint and additive processing. Developed for the direct dosing of liquid paint and additives into the mixer, it offers an unprecedented level of precision, safety, and ease of use.

Whereas previously canisters had to be lifted manually onto ladders and liquids laboriously poured in by hand – a task that was both physically demanding and associated with considerable accident risks – the MODS24 makes work significantly easier. The system enables automated, direct, and precisely controlled dosing without employees having to lift or open heavy containers.

Greater safety, less strain

The MODS24 significantly reduces the risk of accidents – no more risk of slipping, spilling, or back injuries. The simple handling and automated dosing system significantly improve both safety standards and working conditions.

Automation and precision

Thanks to the PLC-controlled automatic system, dosing is precise and reproducible. Once the density and target quantity have been entered, the system automatically takes over the dosing process – sources of error due to manual handling are virtually eliminated.

Mobility and ease of maintenance

The compact design allows transport in the trunk of a car, which means that the MODS24 can be used flexibly at various locations. In addition, the system is low-maintenance—an automatic rinsing program significantly reduces the cleaning effort. The device can be rinsed automatically using a water connection.

Increased delivery rate

The devices have become significantly faster with increased throughput and flexibility of use. Particularly suitable in environments with increased throughput or frequently changing recipes or quantities.

The MODS24 stands for modern, safe, and efficient mobile dosing technology. It combines mobility, precision, and occupational safety in a compact system and shows how automation can set new standards even in craft-oriented areas.

CONTACT

BM-Anlagenbau und Dosiertechnik GmbH

Werftstraße 11

31789 Hameln/Germany

+49 5151 9 96 96 80