Carbon-reinforced concrete pilot facility –

Automated, digital production of carbon-reinforced concrete components

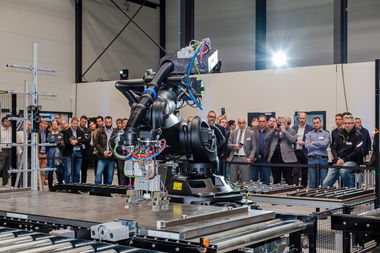

In 2019, the decision was made to establish the carbon-reinforced concrete pilot program with its Dresden, Aachen and Leipzig sites. In Leipzig, the Institute of Concrete Construction at Leipzig University

of Applied Sciences was commissioned with building a model factory for the automated, digital production of precast elements made of carbon-reinforced concrete, which was inaugurated on September 29, 2022.

Whereas quick and largely automated processes have been in place for many years for the tailor-made production of steel-reinforced concrete elements, the manufacture of carbon-reinforced concrete

components still predominantly involves manual work steps. Existing technical knowledge gaps must be closed and end-to-end

process chains developed for standardized components meeting a reproducible, high quality standard in order to improve cost and time efficiency in production. The model factory forming part of the German carbon-reinforced concrete pilot program includes a second-to-none demonstrator production line, which makes it possible to examine and optimize the process chains needed for the end-to-end digital, fully automated, highly efficient production of finished and semi-finished carbon-reinforced concrete elements.

The model factory includes four work stations equipped with robots, which cover the core work steps in the production of carbon-reinforced concrete elements, namely the placement and heat treatment of rovings, preparation of the formwork, insertion of the carbon reinforcement, and automated finishing and further processing. Several research projects are already underway at the pilot facility, including, for example, the development of a fully automated quality control system for carbon-reinforced concrete components.

The model factory of the German carbon-reinforced concrete pilot program

was created with the financial support of the Federal Ministry of Education and Research and the Federal Ministry

for Economic Affairs and Climate Action,

the Saxon State Ministry for Science, Culture and Tourism, and the Free State of Saxony.