The impact of sucrose on the process of hardening of cement slurry and mortar mixtures

For a long time, sugar has been known to have an impact on delaying the process of cement setting and hardening. There is little data contained in the literature on this subject and it is often contradictory. Therefore, this article presents tests of cement slurries and mortars performed to verify this data. References see online article.

For a long time, sugar has been known to have an impact on delaying the process of cement setting and hardening. There is little data contained in the literature on this subject and it is often contradictory. Therefore, this article presents tests of cement slurries and mortars performed to verify this data. Studies were carried out to test the initial and final setting time of cement as well as the flexural and compressive strength of mortars with varying sugar content. The obtained test results partially differed from those suggested in the literature. This indicates the need for additional control tests. Their results will allow for a fully controlled use of sugar in concrete construction as a retarding admixture.

1 Introduction

Every practicing engineer knows very well that sucrose, i.e. food sugar, is the enemy of cement and products made with its use. From my own practice in the laboratory, I remember a case of a problem with obtaining the strength of concrete samples. It turned out that the aggregate for the concrete was delivered in bags that had been used for sugar before.

There is a widespread belief in the “builders” community that even a small amount of sugar completely blocks the cement setting process and finally drastically decreases concrete strength or even reduces it to zero. There is little information on the influence of sugar on cement properties available in the literature, and this information is sometimes contradictory.

An analysis of the current knowledge on this subject was made in the literature, and later, in order to verify this knowledge, laboratory tests of cement slurries and mortars treated with sugar were performed. Tests of the initial and final setting time of cement slurries were made as well as tests of the flexural and compressive strength of cement mortars with varying sugar content.

2 Sucrose as an admixture delaying cement setting

Retarding admixtures are frequently used in construction practice. Most often, they are used for concreting large surfaces and when using large volumes of concrete. They are also used during concreting at high temperatures and during the transport of concrete mixes. The skillful use of the retarding admixture also enables the correct revibration of the installed concrete.

Among organic compounds, carbohydrates such as glucose, sucrose, starch and cellulose are particularly effective in delaying concrete setting. According to [3,4], the addition of 0.01 to 0.05% of sugar in relation to the cement mass is comparable with the influence of phosphoric acid. It has a big impact on delaying the setting process, it improves the workability of the concrete mix and practically has no effect on its 28-day strength. According to many authors [2,3,5], a sugar content of up to 0.25% in relation to the cement mass does not have a significant impact on the basic physical and mechanical properties of concrete. It is commonly believed that a 0.05% sugar content in relation to the cement mass enables the setting to be delayed by approximately four hours without any negative effect on the in-use performance of concrete. According to [3,5], the chemical and mineralogical composition of cement has a significant impact on the intensity of sugar influence. According to [4], the slowing down of the setting process may be the result of covering the grains of the fast-setting C3A by sugar dissolved in water. Therefore, the intensity of sugar impact should be tested experimentally in each case. The effectiveness of retarding admixtures depends on the air temperature. It was observed that the intensity of the retarding admixture was inversely proportional to the ambient temperature.

The effect of adding sugar to cement is sometimes used in construction practice. A small amount of sugar (0.01-0.02%) facilitates the facing processing of decorative concretes [2]. On the other hand, a large amount (> 1%) makes it possible to stop the process of setting and hardening of cement completely. This is useful, for example, in the case of problems with the transport of concrete mixes or the breakdown of a concrete mixer. According to [3], sugar, and specifically the molasses it contains, was used during the construction of the Channel Tunnel in order to counteract the setting of concrete when the immediate washing of the concrete mix was impossible (due to the length of the tunnel).

The highly retarding effect of sugar on cement setting is explained in the literature in different ways. The most common explanation is that sugar blocks the formation of the C-S-H phase [3]. Another important reason is the phenomenon of sugar forming a protective colloid on the surface of the cement grains, which delays the sol-gel transition process. It is also claimed that the calcium sucrose created as a result of adding sugar to cement contributes to the formation of aluminum-silicate gels, which significantly blocks the crystallization process [2].

The use of a strongly retarding admixture in construction practice also has its advantages [5]. The time period in which the heat of bonding is released increases. This reduces the heating effect in concrete, which is particularly important when making massive elements and during concreting at high temperatures. Additionally, the advantage of delaying cement setting and hardening is the possibility of proper development of the concrete microstructure (limiting the formation of micro-contraction cracks) and the possibility of obtaining a higher concrete strength in the long term [1].

3 Test results and analysis

The tests were carried out in the laboratory of the Institute of Construction Engineering at Poznan University of Technology. These included tests of the initial and final setting time of cement with a sugar content of 0.01% to 0.6% in relation to the cement mass and tests of tensile strength as well as bending and compressive strength after 3, 7 and 28 days of curing of cement mortars containing from 0.01% to 0.1% of sugar in relation to the cement mass. A CEM I 42.5R cement was used to prepare slurries and mortars. The setting time tests were performed at a temperature of 20 ± 1 ° C. Standard sand with a grain size according to [6] was used to prepare the mortars. The weight proportion of cement to sand in the mortars was 1:3. The obtained test results are presented in Chapters 3.1 and 3.2.

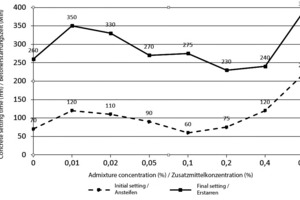

3.1 Testing the initial and final setting time

The obtained test results are presented in Table 1 and Fig. 1. The use of as little as 0.01% of sugar in relation to the cement mass results in a significant delay in both the initial and final setting time. Then, as the sugar content increases from 0.01% to 0.2% in the slurry, its influence clearly decreases. At 0.2% of sugar, both the initial and the final setting time are comparable with the time obtained for slurry without any sugar added. The obtained results are inconsistent with the literature data (“the addition of 0.2% of sugar delays the setting time by 4 hours”).

At the same time, there is a certain consistency here since the addition of 0.25% of sugar does not have a significant effect on the cement properties. A sugar content of over 0.2% in relation to the cement already results in a significant increase in both the initial and final time of cement setting. We can thus expect that 1% of sugar addition to cement results in its “killing”, i.e. complete inhibition of the setting process, which is consistent with the data contained in the literature.

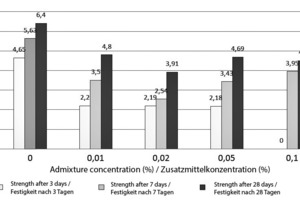

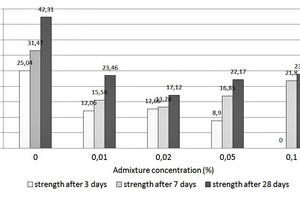

3.2 Flexural and compressive strength tests

The tests of both flexural and compressive strength were carried out after 3, 7 and 28 days of curing of standard cement mortar in laboratory conditions. The tests were performed using standard 4 × 4 × 16 cm samples. Strength tests were carried out for reference samples (without any sugar added) and for the sugar content in the mortar (in relation to the cement mass) equaling 0.01, 0.02, 0.05 and 0.1%. The upper limit of the sugar content was assumed (according to the data contained in the literature) to be in the range not harmful to the durability of the mortar. The obtained results of the strength tests are presented in Tables 2 and 3 as well as Figures 2 and 3.

The results of the analysis of sugar content impact on the 3-day strength of mortar are quite interesting. As little as 0.01% of sugar content already reduces the strength of the mortar by more than 50%, and 0.1% of sugar content completely blocks the hardening process. It turns out that the curing time of the mortar significantly reduces the delaying effect of sugar (which is consistent with the information contained in the literature). The flexural strength tested after 7 days of curing with a sugar content of up to 0.02% gradually decreases, and when the sugar content rises above 0.02% it increases, reaching approximately 70% of the strength obtained for the reference sample with a sugar content of 0.1%. A similar course of changes in flexural strength is achieved after 28 days of curing. With a low sugar content (of up to 0.02%), the strength decreases significantly. With a sugar content of 0.05% and above, a significant increase in flexural strength occurs, reaching approximately 70% of the strength of the reference sample.

In general, similar changes resulting from the gradually increasing addition of sugar to the cement contained in the mortar were observed when testing the compressive strength. After 3 days of curing, the increasing sugar content results in a gradual decrease in strength, reaching zero at 0.1% content. When testing the compressive strength after 7 and 28 days of curing, we initially observed (for a sugar content of up to 0.02%) a gradual decrease in strength compared to the reference sample, and later with a further increase in the sugar content, a gradual increase in 28-day strength to approximately 55% of the 28-day strength of the reference sample. Also in the case of the compressive strength test, the assumption taken from the literature has been confirmed that, in the long term, sugar (like other organic substances delaying cement setting and hardening) causes a significant increase in strength, often exceeding the strength of the reference sample. We can thus assume that a similar effect would be obtained if the strength tests were performed after, for instance, 90 days of curing.

4 Conclusion

After a comparative analysis of the collected literature data and the analysis of the obtained test results, we can draw the following conclusions:

A significant delay in both the initial and final setting of the cement mortar occurred after adding over 0.4% of sugar. Therefore, the information provided in the literature that a sugar content of 0.05% delays cement setting by four hours should be verified. However, based on the obtained test results, it can be concluded that the addition of more than 0.6% of sugar (> 1% is stated in the literature) may completely block the process of cement hardening.

As little as 0.1% of sugar after three days of curing almost completely blocks the hardening process of the cement mortar. Therefore, the information contained in the literature that a sugar content of up to 0.25% in relation to the cement mass does not affect the basic physical and mechanical properties of the mortar has not been confirmed.

On the other hand, the assumption taken from the literature was confirmed that, in the long term, sugar causes a significant increase in the strength of the cement mortar.

The test results presented in Chapter 3 of this article refer to slurries and mortars prepared with a CEM I 42.5R cement. Therefore, it is believed that the information contained in the literature suggesting that the cement phase composition, especially the content of fast-setting C3A, has a considerable influence on the delaying action of sugar, is correct. However, it requires careful verification. Additional tests are also required to determine the influence of air temperature and the specific surface area of cement on the “effectiveness” of sugar.

The presented test results demonstrate that not all the effects of sugar on cement are precisely known and defined. The information contained in the literature with respect to this subject is often inaccurate. There is thus a need for further investigation. Sugar, when used properly, can be a very useful and cheap admixture used in construction practice.