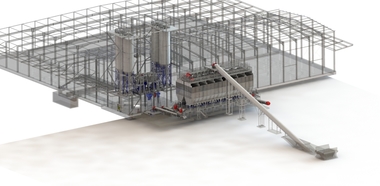

Special design concrete batching plant for Poland

Elkon started a new business partnership by supplying Elkomix-60 stationary concrete batching plant to European leading supplier of track superstructure materials for high-speed railways.

Polish company, which is one of the biggest high-quality certified sleeper producers with many years of experience, is the supplier of half of the track sleepers and the products of rail network in Poland.

Elkon’s tailor made precast concrete plant along with high-speed concrete travelling bucket is supplied for this specific project including all season operation equipments.

The Elkomix-60 is equipped with a 1500/1000 l planetary mixer having two discharge gates: one to feed the production line, and one to wash the mixer.

Elkon planetary mixers are designed to perform high mixing performance for challenging applications providing required homogeneity in the mixture even with shorter mixing times as the mixer turret is rotating around the mixer center point in the meantime mixing stars connected to this turret are circumvolving. Moreover, replaceable inner linings are made of wear resistant Hardox wear plates (SSAB-Sweden) and the mixing paddles are highly wear-resistant cast steel. (NiHard 4). Thanks to these advanced features of Elkon planetary mixers, Polish company ensures the quality of concrete they are going to produce for such special application.

Partner of top quality certified sleeper producer

In the system, the concrete produced by Elkomix-60 is discharged into Elkon high-speed concrete travelling bucket that will deliver the concrete at a speed of 2.5 m/s to the production line. A platform and a special unit for bucket washing and maintenance are installed to implement daily bucket maintenance procedures. On the other hand, the plant is completely ready for winter operation. The heating system and the covers above the aggregate storage bins and main unit along with the mixing block filter allow concrete production to be done in any season. Cement storage is provided in two cement silos of 100 tons each. In addition, the plant is supplied with a special software system to produce reinforced concrete providing utmost accuracy in every batch.

Elkon is proud to be a partner of top quality certified sleeper producer with decades of experience and consistent innovation.

Elkon with its experience and professional approach in manufacturing tailor made batching plants along with its standard models has succeeded to design batching plants according to requirements of its customers from all over the world.