Root causes of green deposits and foliage

effects on concrete block pavements

The number of customer complaints in consequence of discolorations of concrete block pavements has increased considerably, first of all, because of the ever increasing importance of the visual appearance. This paper is focusing on discolorations, which are due to the formation of green deposits, as well as the discoloration of paving products caused by organic components such as foliage.

In consequence of the increasing importance of the visual effect of concrete block pavements in outdoor applications, the number of customer complaints is growing significantly on the topics of „efflorescence“, „discolorations“, „edge damages“ or also the „soiling characteristics“ or the „cleanability“ of paving products. In parallel, the market share of surface-finished and/or mass-hydrophobized products is increasing. Especially, in case of finished products, the final customers assume, as a rule, that these products ensure an almost complete cleanability and that there are hardly any significant discolorations or green deposits on the products even if leafage is lying on the block pavement for a longer period, for example, (see Figure 1) or if the pavement is installed in permanently shaded areas. Statements such as, „Do I really have to remove the leaves every day?“ are definitely not uncommon but the rule.

Against this backdrop, the question arises how the formation of green deposits on concrete block pavements or the discoloration of the products due to the effects of leafage or any other decomposing vegetation are to be evaluated by an expert. In this connection, it is also essential to discuss whether the described expectations of the customers are reasonable. May the visual appearance of the product actually not alter if organic substances, which possibly release tannic acid, remain on the concrete block pavements for a longer period?

This paper presents two controversial questions from this range of topics.

A comprehensive overview of the respective damages is given in [11].

1 Green deposits on the concrete slabs of a pavement

1.1 Exemplary legal dispute

The following presents a legal dispute where the building contractor brought an action against the building materials supplier because the expensive, surface-finished concrete slabs even should have encouraged the formation of green deposits.

During the visual inspection, it was revealed that part of the concrete slabs actually exhibited a significant green deposit. As expected, the green deposits appeared particularly strong on the shaded partial areas on the north side of the building (see Figure 2). However, intense green deposits were also partially discovered on the concrete slabs of the south side of the building; but in the present case, this could be explained by the fact that the slab pavement on the south side of the building was also installed in a permanently shaded area because of a high surrounding wall (see Figure 3).

Figure 4 shows that in this area noticeable green deposits not only had formed on the concrete slabs but also on the masonry bricks of the wall. Regardless of the orientation of the pavement, clearly noticeable green deposits were also discovered on partial areas where planters were placed. It has to be assumed that, when watering the plants, the slab pavement in these partial areas were in contact with considerable amounts of water and with fertilizer.

In the context of the legal dispute, it should be clarified by an expert whether the concrete slabs were deficient because of a significant green growth. An authorized expert contacted beforehand had determined that some slabs showed stronger green growth than others. Without any comprehensive investigations carried out in the laboratory, he concluded that the discolored concrete slabs were deficient and therefore, the slab manufacturer had to bear the costs for the replacement of the slab pavement.

The latest visual inspection of the pavement revealed that not only some concrete slabs but also a great number of the building materials installed on site exhibited a significant green growth. Hence, green deposits not only were found on the complained concrete slabs but also in the joints between the concrete slabs (Figure 6), on the screed in front of the garage (Figure 8), on the concrete block pavement of the neighboring property (Figure 8), on the paving blocks of the street (Figure 9), on the natural stones of the slope protection next to the building (Figure 10) as well as on the masonry bricks of the surrounding walls (see Figure 4).

Thus, far more than just the concrete slabs were affected by green deposits as the findings of the on-site inspection reveal. If the inferior quality of the concrete slabs had been actually the only root cause for the formation of green deposits, why did the other building materials also exhibit such severe green deposits?

Within the scope of the laboratory investigations carried out at MPVA Neuwied GmbH, it was determined that the slabs installed were concrete slabs featuring an absorption behavior and surface drying, as expected. The cleaning tests carried out, in return, revealed that the green deposits could be removed almost completely by just cleaning with water and a brush.

1.2 Root causes for the formation of green deposits

The authorized expert first of all had to deal with the question what influences the formation of green deposits on the material, when answering the question why such severe green deposits had formed at all. In this respect, it should be noted that the formation of green deposits is encouraged, among others, by the below-mentioned points:

Quality of the building materials: The longer the building materials keep moisture, the greater the tendency to form green deposits. Owing to this reason, the tendency to form green deposits increases with an increasing capillary water absorption and a reduced drying speed of the building materials.

Quality of the installation: The workmanship of the concrete block pavement has a comparable influence on the tendency to form green deposits. Hence, the installed building materials are drying significantly slower if the subbase of the concrete block pavement features a high water storage capacity or an insufficient drainage capacity. In this case, the tendency to form green deposits is also increasing considerably.

User behavior: The users of concrete block pavements quite often forget that the behavior of the user as well as the ambient conditions have a significant influence on the tendency to form green deposits, too. If plants, for example, are frequently watered, with the water draining off the pavement, this may also lead to the fact that the building materials remain wet over a longer period, thus resulting in the formation of significantly larger amounts of green deposits. The use of fertilizer (nutrient for the green deposits) even enhances the effect here. Not only the plants grow better, but also the undesired green deposits on the concrete block pavement grow better when using fertilizer on a regular basis.

Ambient conditions: The ambient conditions also play an important role regarding the tendency to form green deposits on concrete block pavements. It is common knowledge that green deposits frequently intensify on shaded sides of a building (mostly on north sides). The shadowing of the concrete block pavement by plants (such as hedges, for example) or other things (in this case by a wall) has the same effect.

Normally, enormous green deposits only occur in practice if several of the above-mentioned influences coincide and the user does not react by adequate cleaning. If a shaded property is concerned, where the plants are frequently provided with fertilizers, it is necessary to clean the pavement frequently in order to prevent the formation of intensive green deposits.

In the example presented above, the authorized expert assigned by the court concluded, contrary to the authorized expert assigned beforehand, that the quality of the building materials used was not responsible for the significant formation of green deposits. Rather, unfavorable ambient conditions (shadowing) existed on site as well as an inadequate cleaning behavior of the user.

In respect of the user behavior, a clear correlation was noticeable, at least partially, between the formation of green deposits and the watering of plants (use of fertilizer). Due to the knowledge that the green deposits could be removed in the laboratory by means of water and a brush without any problems, it seems likely that the user behavior has an influence here.

2 Discoloration of pavements through the effect of foliage

2.1 Root causes of discolorations due to foliage

Customer complaints because of an effect of foliage on the surface of paving blocks or slabs lead to legal disputes even more frequently. In this case, the users of concrete block pavements frequently installed with expensive, surface-finished products complain about discolorations occurring in the surface of the product, which afterwards can often only be removed by aggressive cleaning agents.

In case of, e.g., a foliage/leafage effect on the concrete block pavement, the problem is that these organic substances partially decompose with release of tannins. On the one hand, these tannins are substances that chemically attack the hardened cement paste as well as some inorganic surface finishing (silica-based hydrophobic coating) and, on the other hand, they have a significant tendency to discolor. Frequently, these surface changes occur already after a short period and lead to discolorations and in case of surface-finished products possibly to loss of gloss, too (see detailed explanations in [L 12].

The actual problem, however, is that as far as expensive and surface-finished products are concerned, the customers wrongly assume that they do not need to clean these products at all or less frequently („lotus effect“). Statements such as „Even though I bought the expensive slabs, I still ought to remove the leaves every day?“ are not uncommon.

2.2 Expert‘s damage investigation

From a technical point of view, in contrast, it should be noted that even premium-quality pavements treated with well-functioning surface finishing require regular cleaning and even maintenance, if necessary. Nevertheless, at an early stage, these products usually allow for removing contaminations much better than pavements without any finishing. If, however, the contaminations remain on the products for a long period, the occurrence of persistent contaminations should be expected also in case of finished products and they can only be removed again with the aid of aggressive special cleaning agents.

The following section presents a case of damage where brown discolorations occurred on concrete blocks of a pavement (see Figure 13). The building contractor assumed that the leachates of the concrete paving blocks were responsible for the brown discolorations. As the above-mentioned photo demonstrates, the discolorations appear in locally restricted partial areas, whereas paving blocks installed in the direct proximity partially were free of discolorations. It was particularly apparent that significant discolorations were partly also noticeable in the joint area (see Figure 14), without the paving block being affected.

For assessing the cause of the discolorations, parts of the discolored paving blocks were subjected to an orienting glow test at 550 °C. Generally, organic components degraded at this temperature while iron-containing components turn reddish. Brown discolorations, being due to the transportation processes from the concrete block pavements (if this occurs); primarily consist of iron-containing components. Discolorations caused by organic components mobilized from the blocks are only the reason for brown discolorations in quite a few individual cases.

Within this orienting test, it was revealed that the discolorations almost completely disappeared under thermal treatment. This should be regarded as an indication of the fact that the brown discolorations were actually caused by organic components. Cleaning with the aid of an oxidizing and high-alkaline cleaner also resulted in a substantial reduction of the intensity of the discolorations. This finding also indicates that the discolorations are caused by organic substances.

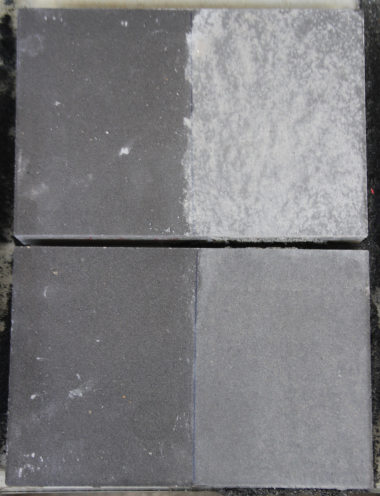

Based on the findings of these preliminary tests, the suspicion arose that the discolorations could have been caused by the leaching of wooden components. For checking this presumption, within a preliminary test, wet wood pieces were placed on paving blocks not being discolored for several days and then the discolorations on the block surface were examined. Brown discolorations occurred in this orienting test, as well (see Figure 15).

Consequently, it must be concluded that the discolorations of the paving blocks were most certainly not caused by leaching products from the concrete block (iron-containing components). On the basis of the investigations carried out in conjunction with the apparent impression of the concrete block pavement, different causes of damage came into consideration.

The most likely root cause was that wood had been lying on the concrete block pavement over a long period and the leachates of these woods had led to the discolorations. However, to provide a proper evidence for this with the aid of the infrared spectroscopy or the gas chromatography (GC/MS), for example, was not required by the client, on the grounds of costs.

3 Summary

The number of customer complaints in consequence of discolorations of concrete block pavements has increased considerably, first of all, because of the ever increasing importance of the visual appearance of concrete block pavements. A comprehensive overview of the different root causes of these discolorations (contaminations, joint materials, efflorescence, etc.) was given in [11] and [12]. This paper was focusing on discolorations, which were caused by the formation of green deposits, as well as on the discoloration of the paving products by organic components (foliage and woods).

Section 1 reported on the influences, which may cause or at least may contribute to the formation of green deposits on concrete products. Section 2 presented discolorations which were presumably caused by wet wood having an effect on the concrete product over a long period.

For the proper assessment of respective complaints, it is essential to be aware of the fact that a wide variety of influences can lead to discolorations on paving products. As a consequence, different root causes should be taken into consideration for the evaluation of discolorations, being confirmed or excluded by means of the applicable methods of analysis.

REFERENCES/LITERATUR