Rehabilitating our ailing transport infrastructure – Use of Ultra-High Performance Fiber-Reinforced ShotCrete (UHPFRSC)

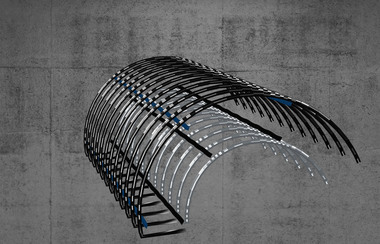

Innovative and efficient concepts are needed for rehabilitating and upgrading our ailing transport infrastructure. For the purpose of repairing such structures, a system is currently being developed at Munich University of Applied Sciences that involves the use of Ultra-High Performance Fiber-Reinforced ShotCrete (UHPFRSC). Experimental tests of the material characteristics of UHPFRSC proved its reliable adherence to the specifications defined for UHPC. UHPFRSC can be applied in an almost rebound-free shotcreting process. The particular effects of this process on concrete compressive and tensile strength as well as on its modulus of elasticity were studied in detail. The fiber orientation and bond strength of the UHPFRSC are essential for upgrading and repairing reinforced-concrete structures. Under axial tensile loading, UHPFRSC exhibits a consolidating behavior associated with a pronounced multi-cracking pattern, with a beneficial effect on the durability of the material.

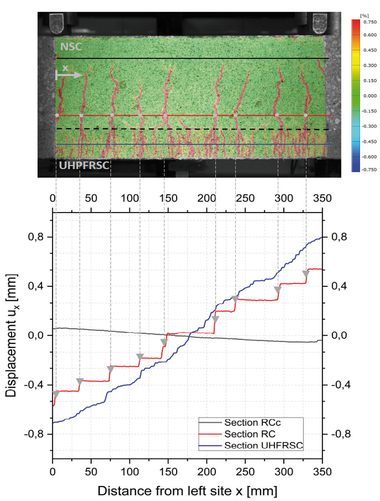

In collaboration with infrastructure operators such as the Bavarian highway authorities, the planning and building department of the State Capital of Munich, and the Federal Waterways Engineering and Research Institute, damage patterns of existing structures and potential fields of application of UHPFRSC are being discussed in order to focus on the most promising types of use. The tests of the composite system formed by the existing concrete and the UHPFRSC focus on the material’s cracking pattern and bond properties and also encompass the investigation of its characteristics relevant to durability, including chloride penetration resistance, and its load-independent deformation behavior. The series of experimental tests will be followed by their simulation, development of design models, and analysis of the chloride penetration behavior in existing micro-cracks.

This paper will provide an overview of the research project and report on recent tests carried out as part of the current project.