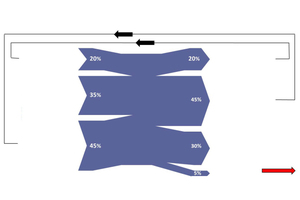

Re-evaporation of hot

condensate

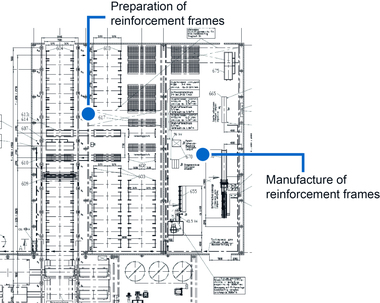

In the production of AAC blocks the focus lies on unit costs when it comes to manufacturing this wall material. Well-proven production methods ensure that these blocks are manufactured in a consistent quality. Thus, it is hardly possible to differentiate the market through the product quality. Though a company is only able to strengthen its market position on the commercial side by reducing the unit costs of production. Owing to permanently growing costs, here the emphasis is on saving fuel and fresh water as well as avoiding waste water in the production process. In the AAC industry this can...