Qualitative leap in air-coupled ultrasonic testing of concrete

A new non-contact ultrasonic testing technique from Sonotec promises previously unattainable precision and reliability in non-contact testing of strongly attenuating materials such as concrete.

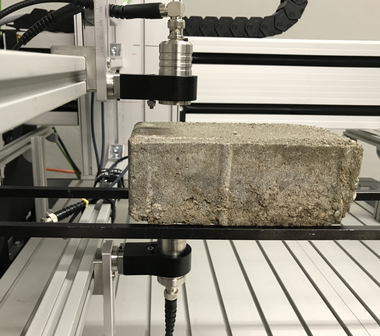

The Sonoair R&D end-to-end solution consists of a scanner, ultrasonic probes, industrial computers as well as special software designed for specific requirements of development and testing laboratories in research facilities, universities and companies. It is also intended for industrial applications, such as in construction materials production and concrete processing. The innovative solution based on sensor engineering of this international technology leader for air-coupled ultrasonic testing is the result of cooperation with the ultrasonic research center (FZ-U), both of Halle (Saale), Germany.

This compact system for testing and evaluating test specimens of fresh and hardened concrete is, for example, suitable for detecting flaws, voids, cracks as well as inhomogeneities such as gravel pockets.

Highest precision in non-contact ultrasonic testing

“Our process is significantly more sensitive and therefore more precise than any other non-contact ultrasonic test method worldwide,” says Sonotec’s Managing Director Michael Münch. This results from the extremely high transmission power at a power rating of up to 800 V in combination with a previously likewise massive amplification of the signals received with extremely low internal noise (below 1 nV/√Hz).

Precision engineering plus scientific support

“Close cooperation of his company with the independent industry research center FZ-U, moreover produces additional user benefits,” explains the Sonotec CEO. “Our partners there have accumulated many years of expertise in scientifically processing challenging test assignments – with results that we are able to activate at any time.” Dr. Mario Kiel, Head of the Non-destructive Testing Department at the non-profit research institute, sees the decisive advantage of the cooperation mainly in connection with the complete technology package with comprehensive science-based service –“… in particular when it comes to critical questions.” In this way, the basic testability of a specimen could be quickly assessed, and the technology feasibly matched with a special testing problem. Comprehensive questions could then be addressed in joint research projects, if required.

Advantages for quality assurance and new developments

René Tatarin, research associate in the Research Department for Construction Materials of the IAB - Institute for Applied Construction Research Weimar gGmbH – in Weimar, Germany, is likewise convinced of the great practical benefit of ultrasound-based non-contact testing methods in the concrete sector. Tatarin, a construction engineer currently doing his doctorate in the area of laser-based acoustic methods, sees the special benefits of non-contact acoustic testing methods in the development of new construction materials, in testing of fresh concrete and for assessing durability. “Time- and space-resolved assessment of structural composition, structural difference and changes to laboratory specimens and samples from construction work offers considerable potential for reliable assessment of relevant properties in materials research and quality assurance,” says Tatarin.

Ultrasonic probes with piezocomposite technology

Sonoair R&D has new, especially sensitive CFC probes that provide precise resolution beginning with an error range of one millimeter for the highly diverse analytical tasks. They owe their stable reproducibility at identical acoustic properties to in-house production with piezocomposite technology.

The system is designed with up to four probe pairs suitable both for investigating materials and building components and for in-house development of new processes. Its multi-channel capacity permits high measuring speeds. Simultaneous use of probe pairs with different frequency ranges, moreover, enables investigation of elements with different wall thicknesses.

Software according to individual applications

The software Sonoware Basic was developed for rapid testing in laboratories and industrial systems. Collected data are generally output as two-dimensional images (C-images). The results can be optimized with the filters and processors from a toolbox provided.

The program version Sonoware Advanced, on the other hand, is meant for developing its own analysis and evaluation methods. It also allows unrestricted access to raw data.

Sonotec offers, on request, application consultations, tutoring as well as support in technical project implementation in advance.

For the near future, it is planned to extend the offer by a Sonoair Industrial variant for plant engineers and industrial customers, which is intended to constructively integrate the new system into proprietary products.