Product innovation: QaverMobile quick tester

The new QaverMobile device was launched this year. In spring, this innovation was first presented with resounding success at Bauma, the world’s leading construction material and equipment trade show held in the German city of Munich.

The Qaver brand name is a combination of Q as the first letter of the word “quality” with the four last letters of the word “paver”. It thus stands for quality control in the manufacture of concrete products by means of compaction measurements carried out for freshly produced items. Qaver measurements deliver concrete porosity values, which, in turn, permit conclusions regarding concrete mix design, machine settings, and product moisture. Furthermore, measured values provide information on the water absorption and freeze-thaw resistance of finished products as well as on the suction behavior of concrete products, which is particularly important when wanting to apply coating products.

Small and easy to operate

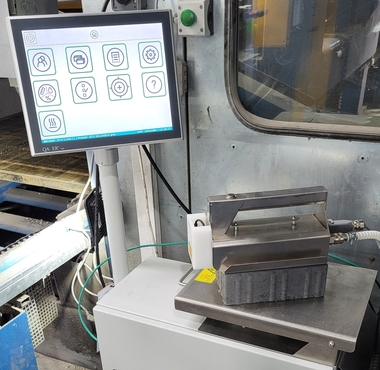

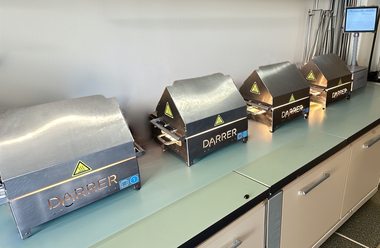

Although all Qaver models deliver the above set of data, the QaverMobile device works completely without administering and configuring products. Measurement results are immediately shown on the display of the handheld device depending on predefined limit values. This provides the advantage that the device is considerably smaller and much easier to use as it merely consists of a portable stainless-steel housing and a handheld unit that includes the digital screen mentioned above.

QaverMobile is a quick tester designed for immediate use and complements the QaverTec product range. It is suitable for manufacturers that do not require the complete range of documentation capabilities provided by other Qaver series. This device is an entry-level option within the Qaver technology and enables simple quality assurance.

Communication

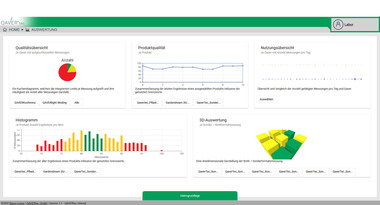

in closed networks

The development of the new Qaver device was complemented by revised and upgraded software options. For instance, the networking capability of the QaverLight and QaverBase series makes it possible to communicate within closed enterprise networks. Moreover, the integrated custom database link is used to directly communicate with the latest generation of block-making machines supplied by Hess, the equipment manufacturer. In this setting, Qaver devices (Base and Light series only) receive product parameters directly from the block-making machine. Paver quality parameters recorded by the Qaver system can be viewed in combination with the machine log at any time.

Qavertec application technicians will be available for questions, comments and ideas at any time. The company website at //www.qavertec.com" target="_blank" >www.qavertec.com:www.qavertec.com provides additional information about the individual Qaver series and the new networking capabilities.