Prefa Brno targets optimization of pipe production

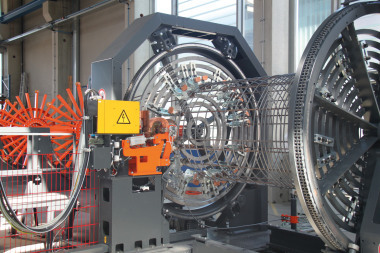

Mbk stands for technical knowhow, ingenuity, high quality standards, and high priority for customer needs. These characteristics enabled the company to develop into one of the leading manufacturers of welding machines and systems for the building and concrete industry. More than 900 welding machines and a total of 1,100 machine systems have until now been sold to more than 60 countries in the world. In August of 2015, an ESM-250-R cage welding machine was delivered to the Czech Republic.

Made in Germany and the high quality standards that this stands for – as well as maximum engineering design expertise, high-tech production, and well-organized after-sales service –these benefits have convinced customers all over the world. Prefa Brno, a major manufacturer of concrete products in the Czech Republic, for example, contracted the mechanical engineering company Mbk Maschinenbau when it became necessary to replace a 30-year-old machine.

Prefa Brno manufactures precast parts for industrial structures, concrete products for roads and sidewalks, as well as paving blocks and curbstones. Concrete components for wastewater disposal such as manhole rings, manhole bottoms, and concrete pipes are among the mainstays of the company’s production program – as is the production of reinforced concrete pipes.

Efficiency, cost minimization, and energy economy

Production with this three decade-old welding machine was anything but efficient: the costs for wear and spare parts and for energy consumption were relatively high. The fact that the welding technology was so outdated made production under aspects of cost efficiency impossible; new investment was inevitable. One of the purposes of the investment was to achieve savings in energy and to implement benefits such as efficient production and minimization of the need for wear and spare parts.

Mbk engineering, technical data, prices, and discussions with other MBk customers convinced Prefa Brno that the ESM from Mbk could meet all requirements.

Ing. Pavel Navplave, Senior Technologist at the Straznice plant, reported that the installation of the ESM-250-R cage welding machine in August of 2015 has had a lasting effect on day-to-day production at Prefa Brno. The customer is satisfied with the machine’s extraordinary reliability, durability, and robust construction. Owing to its great flexibility, the ESM can be easily integrated in day-to-day production. The change to different dimensions at the push of a button and the linkage programs for the inner and outer cage enormously facilitate operations. The tightest production tolerances guarantee exact and straight cages.

Smooth commissioning

A range of additional features ensures great cost effectiveness: maintenance and energy costs are minimal, no cost was incurred for additional structural measures, since no foundation was needed for the machine. And labor costs are also minimal – only one operator is needed for the machine.

It goes without saying that the ESM cage welding machine satisfies the strictest safety standards (CE). A large number of optional accessories makes the ESM even more attractive to the user.

Jiri Janek, Plant Manager for the Straznice production facility, reported enthusiastically on the smooth commissioning of the system. The workers, following comprehensive training, were immediately able to manufacture all the required reinforcement. Since commissioning, there have been no downtimes in production of the reinforced concrete pipes at Prefa Brno. And, in addition to high production stability, yet another conclusion can be drawn after a few months: the costs of reinforcement production are now considerably lower.

Outstanding service

Janek is full of praise for the outstanding production quality, the ease of operation, the cost-efficient exchange of wear parts, flawless after-sales service, and the fact that only a single work shift is required for achieving a positive operating result. He expressly emphasizes the advantage that the ESM model, thanks to its sophisticated design, is subject to little wear, and that the replacement of wear parts is now easier and faster.

The customer is very satisfied that all requirement parameters have been met, and that he can enjoy a number of additional benefits. Owing to the constellation of the outstanding collaboration of the Mbk partner Jami Praha and the company Prefa Brno, matters such as transport, installation, and commissioning proceeded smoothly, in addition to flawless production. Everyone involved was able to depend on everyone else.

The ESM model from Mbk makes the production of concrete pipes at Prefa Brno much more efficient, and the company is now setting new standards for Czech pipe production.