Plastic shrinkage and cracking in 3D-printed concrete elements – mechanisms and countermeasures

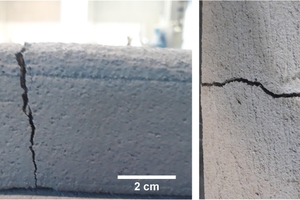

3D concrete printing has the potential to achieve a breakthrough in the construction industry. However, a number of challenges need to be overcome. An important step for transferring the 3D concrete printing technology into real-life application is to minimize and prevent the plastic shrinkage of printed concrete elements. Plastic shrinkage and the resulting formation of cracks occur at an early age of the concrete and can have negative effects on durability, fitness for use and esthetic appeal. The Figure shows the damage caused by plastic shrinkage in a 3D-printed concrete element. The reasons for an increased risk of pronounced plastic shrinkage and cracking associated with 3D printing are:

1) missing formwork to protect fresh material from water loss;

2) problems with curing;

3) use of material compositions with an increased content of powder and cement paste.

Whilst the problem of shrinkage cracking in concrete building elements manufactured using conventional construction methods has been sufficiently researched, little research has been done on the mechanisms of and measures for preventing plastic shrinkage in 3D-printed concrete building elements. In a research project, the Institute of Construction Materials, TU Dresden, is currently analyzing the mechanisms of plastic shrinkage in 3D-printed concrete structures and the resulting formation of cracks, developing new approaches for quantifying the amount of plastic shrinkage, and designing preventive measures.