New testing facility with high-performance turbine mixer presented at bauma

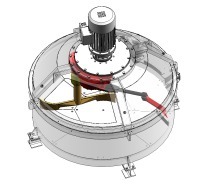

Teka Maschinenbau GmbH presented its new testing facility at this year‘s bauma in Munich. The core of the extensive test station is a high-performance turbine mixer THT type E-1-III with a maximum capacity of 600 l or 960 kg.

Teka Maschinenbau GmbH is one of the leading suppliers of high-performance mixers and plant modernizations as well as of complete custom batching and mixing plants for the concrete products and precast concrete elements industry.

A great many well-known concrete plants have been using Teka turbine mixers with success since the presentation of the new Teka high-performance turbine mixer. Since then the THT turbine mixer has proven itself a hundred times over and is mainly used for high quality concrete products or difficult mixing tasks, including facing, colored, fiber-reinforced and polymer concretes as well as self-compacting and ultra-high strength concrete, and it achieves outstanding mixing results with the most diverse filling quantities (even with ultra-small quantities). The new THT series has also proven itself to be ideal with refractory and dry building materials.

In recent years a large number of concrete plants in the German-speaking region have been modernized with the new turbine mixer in order to meet the customers‘ more demanding concrete requirements.

The core – a high-performance turbine mixer

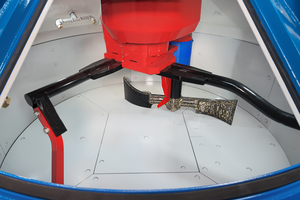

Teka presented its new testing facility at this year‘s bauma in Munich.The core of the extensive test station is a high-performance turbine mixer THT type E-1-III with a maximum capacity of 600 l or 960 kg. It is equipped with a 30 kW drive motor. The turbine mixer is also equipped with LED lights in the interior of the mixer for the easy observation of the homogenization phase during mixing. Furthermore, the mixer has an automatic water dosing unit with a moisture measuring sensor for determining the exact moisture level in the mix.

In addition to the mixer platform, which can be reached via two separate stairs, the testing facility has a complete weighing platform with catwalks and railings. The testing facility also has an independent operating console for the control of the test station, including a frequency converter for the main drive of the mixer that ensures the ideal speed of rotation of the mixing turbine to match the respective mix.

Versatile range of uses

The Teka turbine mixer is mainly used for the following special concretes or by the following concrete manufacturers:

by producers who manufacture many different, high-quality products and therefore frequently change both products and color.

for concretes that have a very high ultra-fine particle content in the aggregates, as for example in the case of facing concretes, self-compacting concretes, etc.

by producers who have to work with small or ultra-small quantities.

In practice, small quantities of less than 10 % of the maximum mixer capacity can be mixed for special products.

The composition of the mixer depends on the individual customer‘s specific requirements in combination with the required components and not, as would usually be the case, on the maximum capacity of the mixer. Each individual mixer can be put together so that it is ideally suited to the respective product to be mixed.

The outstanding properties of the new turbine mixer series can be summarized as follows:

Guarantee of an enormous product variety by the user

The patented mixing turbine guarantees a very large product variety, among other things through the possibility of operating with very different mixes, batch sizes and even ultra-small quantities in one mixer. In practice, small quantities of less than 10 % of the maximum capacity of the mixer have been optimally mixed – and with very demanding concretes at that.

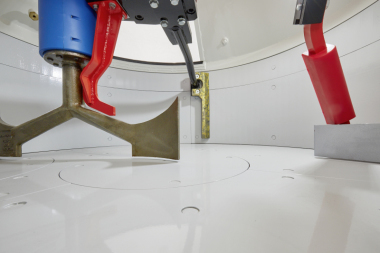

The patented mixing turbine guarantees complete discharge in extremely short times for the purpose of product changes as well as extremely fast emptying of the mixer. It has also been possible to shorten the mixing cycle with regard to mixing and emptying times. Emptying times of less than 50 % of those of a regular planetary mixer are no rarity. A further decisive advantage is the interaction of mixing turbine and clearing arm, which guarantees extraordinarily fast complete discharge.

Ultra-intensive mixing for special and high-performance concretes

The patented mixing turbine and the „swing & throw“ effect guarantee an optimum mixing effect even with the most difficult special concretes and high-performance concretes. A virtually straight moisture measurement curve and the corresponding optimum mixing-in of the mixing water are assured. Destruction of the grain and the resulting (undesired) change in the grading curve are ruled out.

Very low operating and maintenance costs

„Due to the special shape of the mixing turbine and the low number of mixing tools, wear is very low in comparison with other types of mixer. Apart from that the mixing turbine can be equipped with a tungsten carbide coating“, explains Teka‘s CEO Markus Gartner.

Further benefits are the very low cleaning costs or long cleaning intervals with minimal cleaning times, which are ensured by the very low number of mixing tools and thus adhesion points as well as a dedicated scraper for the mixing turbine. In practice it has proven to be the case that the dirt and cleaning effort in the mixer can be reduced to a minimum through the scraper fixed to the mixing turbine, among other things. These advantages are of great importance in particular in the case of frequent product and color changes. The low wear and associated low wear costs as well as the low cleaning effort lead to low servicing and maintenance costs. The height of the mixing turbine is also easy to adjust so that the turbine can be adjusted optimally with respect to the base of the trough, thus reducing wear to a minimum and ensuring very fast and clean complete discharge.

High energy efficiency

The drive power is adjusted optimally to suit the mix and the specific mixing task. There is a choice of different motor and transmission versions with the same mixing chamber. The power of the drives is thus used to the optimum, leading to a correspondingly high energy efficiency.

“In the meantime, the turbine mixers have proved themselves in practice for many well-known manufacturers of concrete products and with a variety of concretes, including the most difficult ones.

The Teka high performance turbine mixer is generally ideally suited for the most difficult mixing tasks and a wide variety of batch sizes. This enables the operator to manufacture a wide range of concrete goods.

Interested concrete producers can either carry out mixing tests at the Teka factory in Edenkoben (Palatinate) and see the benefits of the turbine mixer for themselves, or borrow the testing facility for test purposes in their own plant.