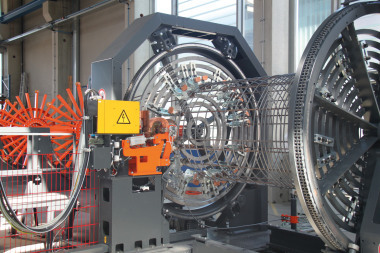

New cage welding machine for concrete mast reinforcement

The LSM-150-C cage-welding machine from the company mbk, according to the manufacturer, is an absolute world first. The machine was developed for manufacture of circular and conical reinforcement for precast concrete masts and poles. The reinforcing cages are manufactured in diameters ranging from 200 to 1,450 mm and in lengths of up to 24 m.

Additional applications for the LSM-150-C can be found in foundation engineering – and wherever bore piles are needed. The stable construction method makes the LSM-150-C highly suitable for rugged day-to-day operations in steel and precast plants.

New electronic spot-weld control

The LSM-150-C welding machines feature a new electronic spot-weld control system. The resulting high-performance welding achieves maximum and highly precise welded quality.

The LSM-150-C machines, moreover, stand out for outstanding flexibility in the production process. This is achieved with an automatic rapid adjustment function, ensuring simple conversion of cage geometry.

The cage lengths of type LSM-150-C range from 8,000 to 24,000 mm and the longitudinal diameters, from 8 to 13 mm. Additional diameters are optionally available. Production is possible of cages with up to 48 longitudinal wires at the base (1,450 mm) and up to four longitudinal wires at the top ends (200 mm). Extension of automation, by means of a DRA-E straightening and cutting plant, enables exact matching of the longitudinal wire feed to production processes, in order to supply the desired length to the automatic longitudinal wire magazine.

The diameters of the winding wire range from 6 to 8 mm. The great variability of the winding wire pitch is one of the outstanding characteristics of the LSM-150-C. The pitch ranges from 20 to 250 mm and can be adjusted in the cage program, based on customers’ specifications; conicity ranges up to 15 mm/m. A clearly organized touch panel and IPC/PLC control enable great ease of handling and programming. The settings for the reinforcement cage and the weld data can be easily saved, which greatly facilitates the daily routines of production staff.

Online customer support and remote maintenance

Hydraulic longitudinal wire clamping, the longitudinal wire supports, cage supports, adjustable reel mountings, the motor-driven winding wire reel, simple winding wire guidance up to the weld point, and the low-frequency welding technique of 125 kVA 50 Hz: all of these features ensure stable production processes. The machine is controlled by a Siemens Microbox (PC) and Soft-PLC (Win-AC); a UPS controls the PC shutdown procedure.

The voltage rating is 400 V, with 50 Hz line frequency: ratings that can be optionally adapted based on the country of use. The standard ambient temperature is up to +40 °C, with the possibility of increase to a specific regional temperature of +55 °C.

Customer support provided through the mbk service team can take place at any time via LAN connection and mbk remote maintenance systems.

The company mbk Maschinenbau GmbH is ISO-certified and manufactures all machines based on the latest European Machinery Directives.

Worldwide networking of mbk

One prime element of mbk philosophy is the high degree of individualization. Customized coordination of machine specifications to the customer’s requirement profile takes place in close collaboration with the in-house engineering team. The optionally available extensive accessory program offers a high degree of flexibility in an innovative industry. This ensures that specific configurations of and/or extensions to the machine can be made at any time to ensure competitiveness in a rapidly changing market.

Customer orientation at mbk is understood as active communication with customers and fast reaction to their requirements. A system of worldwide networking among customers, partners, and subsidiaries makes this possible so that ideas can be developed in the company Competence Team on an ongoing basis and brought to series production. The LSM-150-C is the answer to demanding customer requirements. It enables mbk to meet and patent solutions to challenges in innovative services to set a new standard in production of conical reinforcement cages.