Multi-story logistics buildings in precast design for

self-driving robots

Rapid advances in technological innovations in the field of logistics and materials handling technology lead to new challenges as regards the logistics buildings in which such technologies will be operating. Thus, for example, in case of logistics buildings for Internet commerce there is obviously a trend towards self-driving robots. This means that the workflow in contrast to the previously usual procedure is totally reversed, because in the past the employees went to the racks and retrieved the goods there and prepared them for dispatch. This required a large number of employees, who were moreover exposed to severe physical strains. Therefore, the robotic-based technology not only reduces the staff requirements but also the physical strain at work.

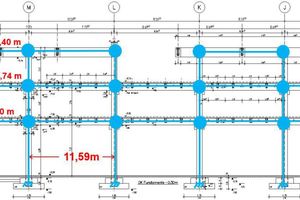

Self-driving robots require large areas but manage with relatively low floor-to-floor heights (< 4.00 m), so that there is a need for multi-story buildings instead of high single-story warehouses. By the present example of the logistics building of Amazon located in Mönchengladbach, it will be demonstrated how such a building looks like and how it can be implemented in precast design. In this case, the location caused additional challenges because it is situated in earthquake zone 2 according to DIN 4149 [1].

So for the structural stiffening of this building restrained columns (Fig.) had to be used, owing to the very small number of vertical shear walls.

This in turn meant that all floor slabs had to be separated by means of expansion joints from the vertical structural components such as staircase walls, shafts, etc. For comparatively large horizontal displacements of several centimeters (approx. 15 cm) in an earthquake event, a corresponding joint design was necessary providing for long displacement distances, that had to be taken into account in the later turnkey construction, too.

Another structural engineering challenge was the jointless design of the floor surfaces, which were separated from the vertical walls but were designed without any additional expansion joints over the entire surface, ensuring a floor space with an as even as possible smooth surface.