Modix threaded connections for the Thyssen Test Tower

The Thyssen Test Tower rises 246 m above ground level and has a diameter of 22 m. In the eleven elevator shafts inside, ThyssenKrupp Elevator, beginning in 2017, will test and certify elevators with speeds of up to 64.8 km/h. To carry out the tests, some shafts must have a length of 260 m. But since the height of the tower above the ground was restricted, it extends an additional 30 m below ground level. The entire project, including, underground stories, has a total height of more than 275 m. Facilities inside the building, in addition to the test shafts, include a firefighter lift and a panorama elevator that takes visitors to a lookout platform at a height of 232 m. The platform, with its glazed windows reaching to the floor, provides a fantastic view of the surrounding area. The story below accommodates a large conference room that makes of every meeting an experience.

The building is being erected by Ed. Züblin AG, which also commissioned the architects and the structural engineers. The contract for this structure had not been awarded in the usual way: ThyssenKrupp had laid down a catalog of the requirements that the tower would have to meet and sent out invitations to tender. Various competing construction companies submitted their bids and themselves performed planning and/or outsourced this work to external planners and designers. Züblin promptly decided to commission two well-known names on the architectural scene: Werner Sobek with Helmut Jahn. The result of this procedure and the preceding planning can definitely be termed a success. The construction of the tower has proceeded smoothly up to now, with adherence to the time schedule in all stages.

Load-transferring mechanical connection

The loadbearing ground slab, 2 m thick, was the first structural member to be erected. The engineers in charge ensured that the 700 m³ concrete required would not develop excessive heat during setting: the only way to avoid shrinkage cracks. Casting took around 11 h, with built-in sensors assisting the workers in monitoring temperature development. Sliding formwork was required to meet the tight time schedule. Aside from the challenges always inherent with construction methods of this kind, work at the site was complicated by weather conditions – in June of 2015 it was so hot that a sprinkler system was needed to cool the reinforcement to allow its handling and installation.

A total of around 2,640 metric tons of reinforcing steel was required. However, owing to transport and other technical constraints, the reinforcing bars could not always be delivered and installed in the required lengths. There are, however, two conventional methods for ensuring load-transferring mechanical connections in such cases:

The first method is the classical lapped splicing: two reinforcing bars placed side by side in such a manner that their ends overlap in accordance with the permissible parameters. Once the concrete has hardened, the compression and tensile forces are transmitted via the lapped lengths. However, this method entails a number of difficulties: e.g., the larger the diameter of the reinforcing steel, the longer the required lap length. Many of the bars used for the Thyssen Tower had diameters of 28 to 32 mm. Overlapping would have resulted in a concrete element section that, according to current planning, would not have permitted installation of the reinforcement in the required manner and density. In addition, there was danger that the lapped splices would obstruct the use of the climbing formwork. Accordingly, this method would not have been acceptable in many places.

The second conventional method consists of welding the reinforcing bars together in-situ. But this work is very time-intensive and difficult to perform under the conditions prevailing at a construction site, and may be carried out only by especially trained and approved skilled workers – enough reasons against using this method.

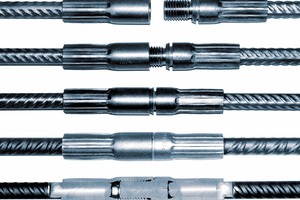

Modix threaded coupler system as alternative

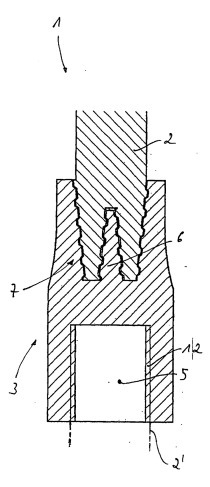

Project managers decided on Modix threaded connections from the manufacturer Peikko, an international specialist for reinforcing steel connection technology. Peikko had already worked for many years with Sülzle Stahlpartner GmbH, located only a few kilometers from the ThyssenKrupp Testing Tower. The two companies jointly offer these threaded couplers. With this system it is possible to establish a mechanical connection in just a few manual steps of work. Even connections between different diameters or between straight and bent bars can be easily achieved. The reinforcing bars are fitted with Modix threaded couplers in the bending shop and must only be bolted together at the construction site. No torque wrench is required for this: only an ordinary pipe wrench.

Another great advantage of the system is that it can be checked by visual inspection to ensure that the connections are secure. No random samples from the connections are required.

Text: Dipl.-Ing. Claudia El Ahwany