Manufacturer of high-performance fibres independent now

Low & Bonar has officially sold its division for high-performance construction fibres with the brand name Adfil to a new owner as from 1st July 2019. The “concrete lab” of the international concern can now carry on independently. With the same name and at the same location, but above all with a new, daring road map. “We want to significantly increase profitability within the first year,” say CEO Tom Winters and COO Ives Swennen, exuding ambition.

Ability to fend for oneself

Since 2014, Low & Bonar have invested significant sums of money in new macro fibre capacities and a brand new concrete lab in Zele, East Flanders. This has resulted in the production of patented fibres which will ensure Adfil remain at the forefront of producing excellent products. Due to other pressures on the business, the international group decided to embark of selling Adfil resulting in the business having come under new control from 1st July 2019. The new owner is a private investor who has repeatedly invested successfully in companies in the past and who thinks in the long term. The daily management will be in the hands of CEO Tom Winters and COO Ives Swennen, who will both also become directors.

The brand name Adfil will also become the name of the new entity, which, will remain in Zele. Apart from that, there is also a sales office in the United Kingdom, employing six technical sales staff.

Market is ripe for macro fibres

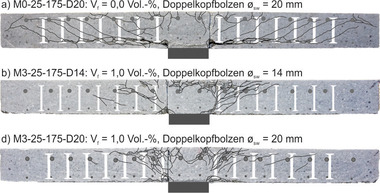

Micro and macro synthetic fibres are increasingly being used to reinforce concrete, as a sustainable alternative and/or supplement for steel reinforcement or steel fibre concrete reinforcement. Adding synthetic fibres in the correct proportions makes steel mesh or steel fibres superfluous in many applications, such as in concrete interior and exterior hard standings.

Until a few years ago, the construction sector was not at all tuned in to the enormous technical sophistication and potential of these polymer fibres. However, gradually the market seems to be ripening for it. Winters: “Increasing numbers of concrete producers, engineering firms and contractors prefer synthetic fibres to conventional steel reinforcement. Those are also the three groups we are hoping to convince.

Since the middle of last year, Adfil has become very active in Belgium, thanks in part to its having obtained so-called ATG certification. “We needed two years to carry out testing. Those tests were done using the worst possible concrete, in other words the worst-case scenario. The ease of working with and the homogeneity of the concrete were thus proven under the most extreme conditions. Thanks to the certification, Belgian companies are now no longer forced to exclusively use steel for reinforcement. In Belgium, approximately 12 million cubic meters of concrete are poured each year, 95% of which is reinforced using steel mesh, so there is still a lot of potential for a better way to carry out reinforcement.” Meanwhile, Adfil has been working together with Interbeton, one of the bigger players in Belgium.

New products and new applications

Adfil now has a turnover of 15 million euros – the volumes are increasing month by month – and supplies its fibres directly to concrete plants or via preferred partners. The latter are commercial players who are co-investing in advance and are pushing their brand fully into the market. As many as 90% of Adfil’s customers are located outside of Belgium, but gradually the concrete plants in the Benelux are becoming attracted to its fibres.

Synthetic fibre reinforcement still has a particularly large margin for growth, precisely because so many markets are still unexplored. The dosage (kilograms per cubic meter) is getting lower all the time, from 12 kg to the current 3 kg. Ives Swennen: “We try to innovate in every facet of the fibre: in color, in bonding the fibre into the concrete and in all the mechanical properties such as impact resistance, tensile strength and stiffness. We want to distinguish ourselves by putting a product on the market that is not based purely on the properties of the fibres, but rather on their actual performance within concrete. In this way, after many external tests, we are now able to test the exact composition of concrete using our fibres for customers and thus to know exactly how it will perform.”

The new owner recently decided to invest in additional sales staff who have both technical and commercial knowledge. In the future, Adfil also wants to reinvest more of its profits into the company. “Because we are now finally standing on our own two feet, we will not only grow step by step, but we also want to make our people happier. We are in the process of becoming a small but very flexible player, in which our employees will also combine various roles. That is why we really want to dedicate ourselves to job satisfaction, because we consider the person behind the employee to be of paramount importance”, they both conclude.