Load-bearing behavior of sandwich façades insulated with mineral foam

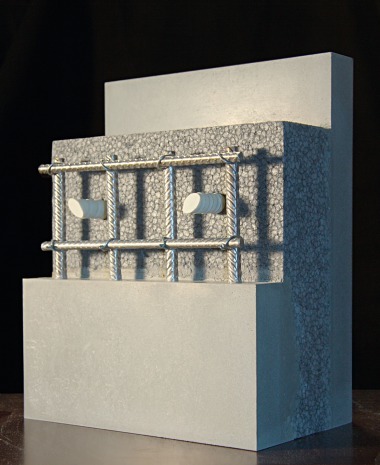

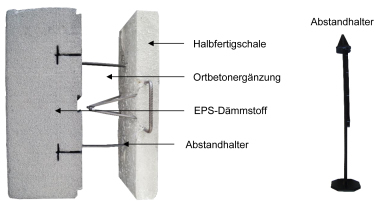

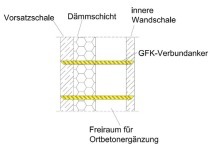

Insulation layers consisting of polystyrene or polyurethane are usually incorporated into concrete façades in order to increase their thermal resistivity to ensure compliance with the specified thermal performance. When producing façade panels at the precast plant, the surface of the insulating material is usually porous or profiled, resulting in a firm bond between the organic insulating material and the mineral-based concrete of the facing and load-bearing layers. Crushing of the sandwich façade elements at the end of their service life thus creates a composite waste material that makes it impossible to recycle and reuse the concrete.

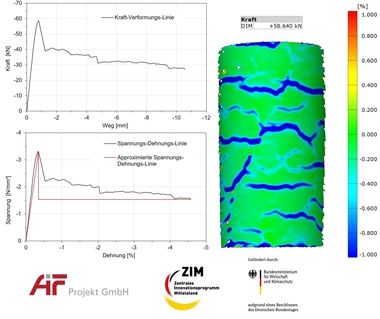

Substitution of organic insulation materials by mineral foam allows for a transformation of the linear sequence of production, use and disposal into a resource-efficient, circular process. Insulating materials made of ultra-lightweight mineral foam are purely mineral-based, non-combustible, freely formable, and self-hardening – and they exhibit a low thermal conductivity. Additional knowledge of the realistic load-deflection behavior of the mineral foam in combination with fasteners in the direction of shear is necessary to ensure the cost-efficient use of mineral foam in sandwich façades. This paper will present experimental tests of the load-bearing behavior of fasteners and ultra-lightweight mineral foam in shear in order to derive related engineering models. In addition, an engineering model for describing the load-bearing behavior in shear will be derived and validated against the results of large-scale bending tests.