Interaction of IT systems in precast construction

The precast concrete industry is the foundation of many other segments of industry and has gained increasing significance in recent years, not least because companies are, among other things, subject to dramatically increasing deadline and cost pressure. Specialized software companies support these companies.

Use of software on large-scale construction sites

The advantages gained by linking precast production with high-performance software become especially evident for the erection of a modern shopping center. The required structural components, such as stairs, floors or sidewalls, are manufactured in the plant to the specifications of the client. These precast parts can be manufactured quickly and cost-effectively in nearly every dimension, shape or color for every conceivable areas of utilization of the construction project. Frequently, special-purpose vehicles are needed for transport to the construction site. Transport logistics plays a key role in this construction phase and is not feasible without an IT system.

Requirements on functionality and flexibility

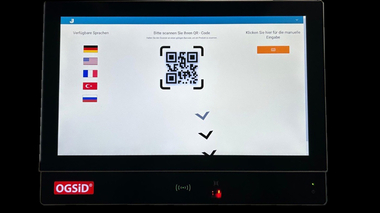

If the client wants to make unexpected and short-term changes, short-term subsequent delivery or production is inevitable. Even if the site supervisor has no mobile device at hand to request an urgently needed structural element, work at the site need not be stopped. The IT systems used by industry-specific software companies, for example, for controlling warehouse logistics and other interfaces, play an important part. They offer precast plants individual programs to enable them to meet current and future requirements and in this way to maintain high quality standards and for controlling efficient workflows.

High-end ERP systems contain tools for resource planning and control, including quotation and order processing, procurement, warehousing, shipping and many other useful tools.

In addition, software solutions are available to offer in particular customers in the construction products sector the possibility to become active independent of locations by by smartphone or tablet.