High precision color dosing system for High Concrete

Würschum has successfully supplied and installed the new Mini-Com dosing system at High Concrete Group LLC in Denver, Pennsylvania in the USA, who is a leading manufacturer of precast concrete.

High Concrete is a well-respected producer of architectural and structural precast wall panels, and one of the nation‘s largest producer of precast concrete parking structures. To make their product line even more suited to the architectural market, High Concrete have added a Würschum fully automatic color metering system to their production plant.

The demands on the color system were extremely high, as there was a need for large batch sizes of up to 60 lbs., and at the same time the ability to achieve a very high color matching capability requiring small pigment batch sizes with super tight metering accuracy tolerance specified.

With the well proven COM 70 metering system for granules in combination with the newly developed Mini-Com series of Würschum GmbH in southern Germany the system requirements could be met to the fullest extent.

Jeffrey Good, VP of purchasing and Phoenix Rann, the VP of operations said that this dosing machine is meeting their production requirements and even exceeded the expectation in respect to the accuracy the system can provide.

Quantities of 0.02 lbs. to 60 lbs. metered

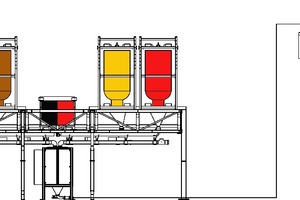

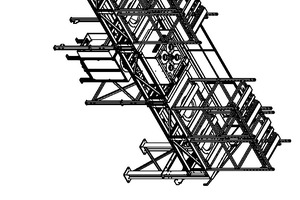

This is achieved by a combination of dosing from four colors from Big-Bag with coarse / fine metering pipes into a high precisions scale COM 70-1. In this scale, quantities of 0.02 lbs. to 60 lbs. can be metered. If the color recipe calls for smaller partial component batches, these will be metered in the Mini-COM unit mounted at the center above the COM 70 unit. Here the batches can go down to 1 ounce (20 g) with an accuracy of 1/10 of an ounce (+- 2 g). This allows for unprecedented color metering accuracy performance to match any custom color an architect may want to specify.

The machine is operated with a standard forklift, which can place the Big-Bags onto the frame. The Big-Bag discharges into a small storage hopper (120 lbs.) which allows for the work to continue during the change of Big-Bag. The vibrating pipe draws the granule from the storage hopper and meter directly into the COM 70 weigh hopper. The vibrating pipe is equipped with coarse and fine metering capabilities to achieve high accuracy. Both speeds, coarse and fine, are freely adjustable for each color separately.

If one or two components of an additive color are below 0.02 lbs. these components are then metered with the super accurate Mini-Com system. Here the weigh hopper is small to allow for the accuracy and the vibrating pipes are operated with a frequency drive module to adjust the speed infinitely. A shut-off valve is provided at the end of each vibrating pipe to keep the metering conditions consistent.

Color shades of very subtle differences

From the Mini-Com weigh hopper the small batches are dropped by gravity into the weigh hopper of the Com 70. Then the completed granule batch is discharged into the conveying pressure vessel. The conveying is done with dry compressed air directly into the mixer. Dust extraction for the mixer is provided to ensure a dust free process. The filling of the Mini-Com hoppers is done with 55 lbs. (25 kg) bags. A larger change container is also available to keep the manual refilling to a minimum.

The main benefit of the combined system is to achieve color shades of very subtle differences. So architects or other customers can choose and change to any color they want. And this color shade especially in pastel tones can be reproduced with a recipe controlled fully automatic system.

With this solution of a combined system of COM and Mini-Com the precast company High Concrete can offer their clients the best possible colored concrete options in the market.