New granule metering system

for Woehe & Heydemann

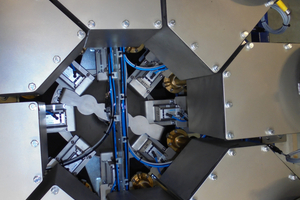

In the spring of 2024, Würschum GmbH successfully installed and put into operation a new Mini-Com 10-8 high-precision, 8-color granule metering system at Woehe & Heydemann GmbH & Co. KG in Kummerfeld, Germany.

The company Woehe & Heydemann stands for the highest standards of quality, technology, and aesthetics in the areas of patio slabs, ceramic tiles, paving blocks, walls, and steps.

Woehe & Heydemann’s exclusive color mixtures enable unique color gradients and complete creative control in adjusting color palettes; which requires high color accuracy for each batch of colored concrete. With the new Würschum Mini-Com 10-8 high-precision type, even very small color batches with a minimum of 20 g and an accuracy of +/- 1 g can be batched, making it ideal for additive color mixing. At peak capacity, color batches of up to 8 kg are possible: i.e., the new system meets all the requirements of Woehe & Heydemann production. The MINI-COM 10-8 color metering system works with two stationary scales (fine and superfine scales), into which all eight electric vibrating chutes can dose. This speeds up the dosing cycles due to reduced travel times. The vibrating chutes feature infinitely variable speed control to work quickly and with utmost precision. To prevent dust from escaping, all transitions are firmly connected and dust-tight.

All this is formula-controlled. For this purpose, the control of the color system has been integrated into the new Bikotronic mixing control system. The companies Bikotronic and Würschum have worked seamlessly hand-in-hand, thanks to their long-standing and excellent collaboration.

Precision and cleanliness are top priorities

In addition to accuracy, cleanliness is also a top priority. Solid-steel containers are therefore used instead of open big bags, since they seal better against environmental influences and are easy to close. This also allows the outlet to be sealed off, especially when lifting the containers after emptying, which prevents even the smallest amounts from trickling out.

The granule batches are pneumatically conveyed via a small 10-liter pressure-discharge transmission vessel directly into the mixer. An automatic dust extraction system for the mixer also ensures cleanliness, since it optimally filters the conveying air before releasing it.

With this system, Woehe & Heydemann has created an excellent basis for the future manufacturing of high-quality colored-concrete products. There are now no limits to the concepts of the product designers at Woehe & Heydemann.

Managing Director Volker Bock says: “The Würschum system perfectly meets all our requirements, and we are very satisfied with the installation, commissioning, training, and daily operation of the color metering system.”

CONTACT

Würschum GmbH

Senefelderstr. 18/1

73760 Ostfildern/Germany

+49 711 44813-0