Heavy-duty dowels minimize space requirement

The urban grounds on Stresemannstraße in Hamburg‘s Altona district had led an extremely sad existence for a long time. Until International Campus AG decided to create living space for young people in vocational training, study or profession, on the plot of land covering about 7,500 m², the so-called „The Fizz Hamburg Altona“. The living quarters were planned by the architectural firm Magnus Kaminiarz & Cie. Architektur. The special feature of the quarter is the tripartite building structure with its silhouette of a folded roof. The focus lies on the three target groups and the forward-looking layout and use concept. However, costs and space requirement also play a decisive role as projects of this magnitude are concerned. In order to make efficient use of the space, columns and corbels were mostly eliminated and heavy-duty dowels with different load-bearing capacities were used instead.

The construction works of „The Fizz Hamburg Altona“ were started in February 2017. Where 770 furnished apartments are erected, divided into three housing categories. Seven floors with an overall gross floor space of 36,000 m² provide young people with living space for studying and working; otherwise they would have difficulties on the housing market in Hamburg. Moreover, the building realized as a closed perimeter development comprises 140 underground car parking spaces, about 500 bicycle parking spaces, several roof terraces and planted courtyards. The three building parts will have separate central entrance areas as well as common areas and support concepts tailored to the respective user groups. The living quarter is expected to open in the summer terms of 2019.

Façade surface covering 37,000 m²

The design idea was primarily based on the later concept of use. The best possible conditions were developed for the residents from the usable floor space, thus providing them with ideal housing floor plans. Due to the diversity of apartments, the building showed various size grids and center-to-center distances which the planners had to consider.

The façade surface covering 37,000 m² perfectly fits in the present townscape. In order to satisfy the diversified and differentiated style of the existing buildings in the district, architect Kaminiarz structured the roof area of the large façade with different folds.

The size and the length of this building require expansion joints in the respective construction sections in order to avoid constraining forces caused by deformations of structural components. Therefore, there are building joints separating the entire building and dividing it into several construction sections. In such a case, a double wall or a double column is frequently used in order to realize the separation of the structural components.

Minimizing the space requirement by means of heavy-duty dowels

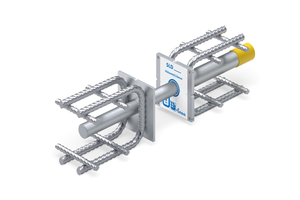

In this case, the architect decided to design the separation of structural components by using Schöck heavy-duty dowels.

The foundation, the slab to wall connections and the floor beam connections were designed with the Schöck heavy-duty dowel type SLD-Q with different load bearing capacities equipped with the respective fire protection collar. The maximum load-bearing level of over 300 kN is achieved by the SLD-Q 150 – this means more than 30 tons per dowel.

The Schöck dowel type SLD-Q consists of a sleeve part and a dowel part which are embedded in concrete into the building components adjacent to the joint respectively. The dowel transfers the loads to the sleeve, hence into the other structural component. The welded-on stirrups and the front plate ensure an optimum load transfer into the concrete. The heavy-duty dowel transfers the high transverse forces into the building joints and allows vertical and longitudinal movements in the direction of the dowel axis. The sleeve is rectangular, thus enabling a displacement of ± 12 mm in the transverse direction. Due to the stiff anchoring body, it is particularly suited for the connection of thin structural components.

„Thanks to the use of dowels they could do without additional double walls and corbels, which otherwise serve as slab support. This has not only aesthetic advantages, but also reduces the effort for formwork and reinforcement. In addition to this, there is a considerable gain in space: Just one wall of only 4.00 x 0.25 mm results in a space requirement of one square meter – the elimination of a load-bearing wall provides for a gain in space which, of course, has also an effect on the sales value,“ explains Michael Kämmerer, product manager at Schöck, the manufacturing company headquartered in the Baden region of Germany. „Because, nowadays, even the building owner is paying attention to efficiency and cost-effectiveness of the projects and the space requirement indeed plays a major role here. The heavy-duty dowels are not necessarily decisive for the architectural appearance, but very important to an optimum use of the existing space,“ Michael Kämmerer added.