Flexible slipformer for prestressed-concrete slab production

The German construction industry is booming. At the same time, the popularity of precast elements is increasing, thanks to prompt delivery and installation, their many positive properties and their versatility. This also affects the demand for prestressed-concrete slabs. Until recently primarily used in industrial construction, these prestressed elements are increasingly used in private homes and residential buildings. The company Elbe Delcon GmbH, one of the leading German suppliers of prestressed-concrete slabs, reacted to the growing demand and invested in an additional slipformer.

Increasing output and reducing conversion times

“We wanted to increase our output considerably and, at the same time, reduce conversion times,” declared Plant Manager Thomas Münzberg. The company, headquartered in Vockerode, halfways between Berlin and Leipzig, specializes in planning and production of individual slab systems and for that reason needs a solution that is as flexible as possible.

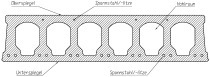

Elbe found this flexibility in the universal slipformer of Echo Precast Engineering. The machine, designed for a rapid exchange of production modules, can be converted within a few minutes. Elbe is thus able to convert production from 10 to 39 cm high prestressed-concrete slabs with 11 hollow cores to elements of 15 to 40 cm height and 6 hollow cores. Following exchange of the respective production module, production can immediately continue. Münzberg is convinced that this flexibility is an enormous advantage of the Echo machines: “In our production, a number of predecessor models are already in operation and we are very pleased; also with their reliability and maintenance friendliness. In all these years we had no production downtime.” The new universal slipformer will continue this statistics. “The machine, we have the impression, is even more maintenance-friendly and even faster to convert than its predecessor models.”

Planned production increase already achieved

The much needed planned production increase has already been achieved. One example for industrial and commercial building is the recently completed “InnovationsCampus 8” office building of Wolfsburg AG in Wolfsburg, Germany. For this project, Elbe manufactured a total of 2,681 m2 Elbe climate slabs, which, via concrete core activation, control room temperatures in the office complex.