Energy-saving walls for an energy transition

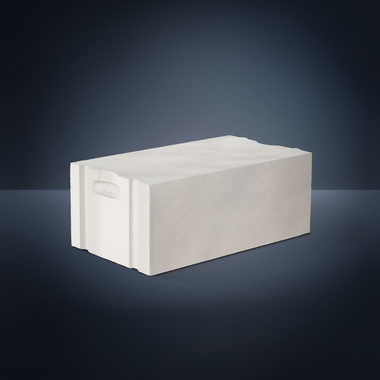

Xella International GmbH is an internationally operating manufacturer of wall and drywall construction materials. The brand names Ytong, Silka, Multipor, Hebel and Fermacell are united under its umbrella.

Energy mostly escapes through the exterior walls. A reliable, energy-focused building refurbishment including thermal insulation systems allows saving a substantial proportion of the energy consumption. Around 80% of the insulation material used consists of polystyrene rigid foam. According to studies commissioned by the NDR - North German Broadcastings - the material used for this purpose...