Digitization: paperless precasting plant

An allocation sheet for every production pallet and an individual slab record for every element on the pallet – a great deal of hardcopy is still being printed in production environments. After all, the costs of a few sheets of paper are negligible compared to the costs of concrete, reinforcing steel and embedded parts. Or are they not? Looking at the amount of overall work involved in a hardcopy printing process and the individual costs – for paper, printer, toner and for waste disposal, to name just a few – this is neither up with the times nor economical.

A calculation example: if 50 pallets occupied with three elements each are produced in one day, this alone amounts to 50 allocation sheets and 150 individual slab records. This adds up to 200 sheets of paper that are printed every day, compiled in the proper order and attached to the pallet.

Why not go digital?

The new UniCAM.10 master computer offers the option of displaying directly at the workstations all pallet allocation sheets and individual slab records. The pallet currently being processed is automatically displayed to the operator on a large screen as it enters the station. The operator can see the information from every position and has both of his hands free. If required, he can zoom into the drawing. As soon as he is finished with the pallet, the individual slab records for the next pallet will already be at his disposal.

The comment function allows entry of comments on the documents. For quick access, the work scheduler in operations planning can use, for example, a tablet or a notebook with touch display. Handwritten comments or markings can be entered with a pen. A decisive advantage over the paper option: the notes are saved together with the documents and are thus available in simply and logically intelligible form at any time.

Laser projection as useful supplement

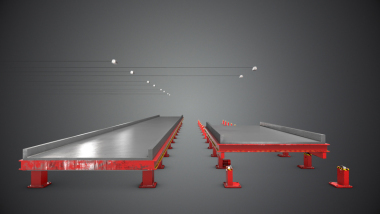

Laser projection is a useful supplement to the electronic individual slab record. Projection of supplements to formwork and embedded parts eliminates the need for measuring when positioning these parts. Laser projection is more or less the digital variant of the plotter. Laser operation is much more cost-efficient than plotters. In addition, it saves cycle time, since the plotting work step is eliminated. UniCAM.10 has already integrated activation of laser projection as a standard feature.

Key figures and reports in real time

And: printing and filing of reports are eliminated when the operators are able to access current data at any time. A whole range of key figures is of essential interest, depending on the manager involved. UniCAM.10 is able to compile figures in any desired way and to display them in a graphically attractive overview. This function is also referred to as dashboard or cockpit. In order to make these individual dashboards accessible anywhere, they are provided in a customer-specific cloud and are continuously updated. The data are of course managed in a secure area and can be accessed only by authorized individuals, with data protection by state-of-the-art security technology. The responsible staff member can now retrieve the latest reports via smartphone, tablet or notebook. The data can be accessed from the office, from the customer onsite or from home.

This new technology enables direct interaction among production, control desk and operations scheduling. But this digital infrastructure at the workstations does not end ongoing developments in production. On the contrary: it offers the prerequisites for implementing many new ideas.