Digital concrete construction by means of additive processes – A critical overview

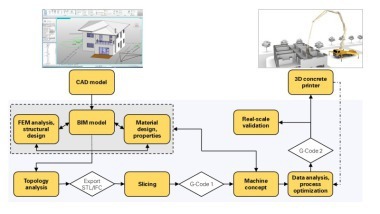

Digital fabrication with concrete (DFC) is a dynamic and rapidly evolving area. The variety of approaches used and of the associated opportunities and challenges is overwhelming. This paper presents a critical overview of the current state of the art in the field of additive manufacturing processes with concrete (also called 3D concrete printing) and identifies current research needs. In addition, a classification framework for DFC processes will be outlined to enable all parties involved in construction projects to classify the individual processes correctly and to engage in a consistent and coherent communication process.

Research needs with regard to printed or printable concrete primarily

encompass the development of methods of material character-

ization in the fresh, hardening and hardened state, including the type of sampling or in-situ measurements, while also defining appropriate quality control criteria, determining the influence of anisotropy as a result of layered material deposition, and complementing existing standards and guidelines accordingly. Regarding the integration of reinforcement in DFC processes, promising approaches should be improved in terms of their robustness, flexibility

and cost effectiveness. In addition, there is currently a lack of research on the bond between the reinforcement and the concrete/matrix, the degree to which printed concrete protects the integrated reinforcement against corrosion, as well as on load transfer patterns and actions as a basis for predicting the load-bearing behavior. As regards design and dimensioning, a particular interest lies in developing methods of topology and design optimization for components depending on the specific printing process and actions the component

is subjected to. It is also unclear which effective component width (relationship between the “homogeneous” component core and edge zone voids or imperfections) to apply for design purposes. Another example is the influence of the position of the printed layers to each other (anisotropy) on the behavior of the component in bending, shear and torsion.

![Fig.: Classification of digital fabrication processes with concrete; based on [1]](https://www.bft-international.com/imgs/1/7/8/3/3/0/5/tok_d3532de9b34a64538333b485b4f39152/w300_h200_x600_y337_12-2_1_Mechtcherine_Abb-54034b2706a248a8.jpeg)