Curing designed to achieve a visibly

better product quality

Not too long ago, the major share of curing racks was designed and built without any type of housing or air recirculation system, but this has changed: in-process quality control is becoming increasingly important amid fierce competition and cost pressure.

Curing is not only about ensuring technically impeccable concrete products. The conditions prevailing during the curing process also influence visual aspects, including the prevention of efflorescence and unwanted color variations caused by humidity and temperature differences in the curing rack. The required dwelling time in the rack is another factor that determines the time to further finishing of the concrete products (such as tumbling, blasting or grinding) or the dimensions of the curing racks.

Curing has a major influence on the density of the concrete fringe zone, and thus also on the durability of concrete products. The achieved density determines the products’ resistance to ambient factors and actions resulting from their use, including the impact of humidity, temperature, frost, de-icing salts and wear. A dense, impermeable surface structure is created if a sufficient amount of water is available for cement hydration. Therefore, curing primarily aims to prevent the evaporation of water from the near-surface matrix. From a production process point of view, a high early strength of the products achieved in the curing process is also beneficial in terms of their further processing and finishing.

Influence of humidity

However, all of the curing objectives mentioned above require a certain degree of hydration to be achieved. The consideration of the mechanisms and parameters that are crucial to this process serves as a starting point to define requirements for curing, which are outlined in the following sections.

The amount of available water is key to ensuring an undisturbed hydration process and thus the formation of a dense concrete surface. The amount of water available in the concrete is directly dependent on ambient humidity. If water evaporates from the concrete surface as a result of poor curing conditions, this causes a disruption to the hydration process if the evaporated amount of water cannot be replaced via transport mechanisms from inside the concrete. A capillary pore system is then created that provides pathways for the ingress of harmful fluids during subsequent use of the product.

The earlier the capillary pores in the concrete fringe zone are filled with cement gel, the more insensitive to drying the concrete becomes. The curing process should thus commence at the earliest possible stage because water evaporation − and thus a slow-down of hydration − may begin to occur even at humidity levels below the saturation threshold. The hydration rate is reduced drastically at a humidity of about 50% [4]. This fact is underpinned by an investigation of strength development at various humidity levels (Fig. 1). According to these findings, a concrete block stored for twelve hours at a relative humidity of 95% reaches a compressive strength that is approx. 20% higher than in the case of storage at 60% relative humidity. Concrete blocks also exhibit greater 28-day strengths when stored at 95% humidity. This situation also permits the conclusion that initial drying does not result in the same degree of hydration as achieved by curing in saturated ambient air.

Influence of air temperature

The composition of the concrete mix alone is insufficient to determine the required curing time. Any such assessment must consider not only the fresh concrete temperature but also the temperatures prevailing during the curing process because cement hydration is more strongly dependent on temperature. This phenomenon is widely known but most curing chambers are not equipped with a temperature-controlled heating system. Although the air temperature prevailing in curing chambers reaches a higher level than under ambient conditions, it still replicates the seasonal fluctuations (Fig. 2). Concrete temperatures are hardly higher than those of the ambient air for the simple reason that the aggregates are stored outdoors, which is why the generated heat of hydration is developing relatively slowly, resulting in only an insignificant subsequent increase in the temperature inside the curing chamber.

Thus curing periods of products in summer must differ from those in the winter season because the degree of hydration of products in the curing chamber should usually remain the same throughout the year. According to Saul [5], concrete maturity is reduced by more than 60% if the curing temperature is lowered from 30° C to 10° C. The calculation of concrete maturity describes the influence of temperature on compressive strength.

Influence of fresh concrete temperature

Using elevated fresh concrete temperatures is a particularly effective means to accelerate the hydration process and thus the development of high early strength levels because this method helps release the heat of hydration very quickly. This approach thus directly meets the requirement of quick curing because the faster formation of hydration products closes the harmful capillary pores more rapidly. As a result, the degree of hydration required to form a dense concrete surface is also reached more quickly. To increase the temperature of the fresh concrete, the aggregate silos and the mixing water must be heated using appropriate units. Although an increase in the fresh concrete temperature is also driving energy cost, there are three reasons for this step:

First, the quality of the products is improved especially under difficult ambient conditions during the manufacturing process, which has a positive effect particularly on their susceptibility to efflorescence. Second, the production periods in the year are extended because the manufacture of products becomes more independent of cold ambient temperatures. The concrete product inventories needed for the spring season are thus attained more quickly. In addition, plant downtimes can be scheduled more effectively in winter. Third, the early strength level required for de-stacking is reached at an earlier point in time.

Efflorescence: influence of curing

Efflorescence compromises the appearance of concrete products and often gives rise to unwanted complaints. Although efflorescence cannot be prevented completely, the type of curing can significantly reduce the occurrence of primary efflorescence phenomena.

Efflorescence is caused by calcium carbonate depositing on the concrete surface. This phenomenon usually results from the transport of water containing dissolved calcium hydroxide from the cement to the concrete surface. The subsequent reaction with atmospheric carbon dioxide results in the formation of calcium carbonate, which remains visible as a haze on the surface and may lend a brighter shade to the concrete. In this regard, Michael Kompatscher et al. [5] note the following: “This efflorescence clogs surface pores and thus prevents subsequent penetration of curing water, which is needed to replace the evaporated mixing water to promote cement hydration. Concrete exposed to such a premature drying process will not reach its full strength and will remain relatively permeable underneath the efflorescence layer.”

Density of concrete fringe zone

As we can see, the transport processes occurring within the concrete matrix are crucial. The concrete is best protected against efflorescence by a quickly developing high density of the concrete fringe zone because it prevents the transport of water from within the concrete to its surface. As a result, reactive layers and efflorescence will form underneath the surface. The concrete retains its original color. This example shows how closely related the mechanisms that give rise to efflorescence are to the objectives of curing.

Low-slump concrete is susceptible to efflorescence particularly prior to and during the curing phase. These phenomena predominantly occur at cool ambient temperatures. On the one hand, the solubility of calcium hydroxide increases with decreasing temperatures; on the other, the rate of hydration decreases at lower temperatures. As a result, the concrete remains porous for a longer period, which promotes the transport of mixing water to the surface.

As the curing temperature increases, the significance of the air temperature for efflorescence is reduced whereas relative humidity becomes more significant because it governs evaporation processes. Michael Kompatscher et al. find in [2] that “curing at a relative humidity of less than 65% increases the risk of efflorescence, whereas it is assumed that curing at humidities between 80 and 95% is perfectly suited to protecting the concrete against efflorescence.”

Requirements for curing

The above correlations can be used to derive a definition of the curing of concrete products that also encompasses aspects related to the production process.

Optimum curing requires the concrete products to be exposed to a curing environment with relative humidities of at least 80 to 95% at the earliest possible stage whilst setting temperatures at which the concrete consistently reaches its early strength level required for destacking during the scheduled curing period.

The following sections outline the measures to be taken to implement the conditions needed for optimum curing.

Curing systems

Concrete products are usually cured in large racks. These racks are housed to separate the inside climate from the surroundings and to prevent the loss of water from the products. Two concepts can be distinguished in this regard:

large curing chambers

individual/separate chambers

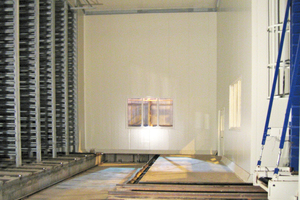

In a large curing chamber, the entire curing rack with its elevator/lowerator unit and finger car is housed and insulated (Fig. 3). This system consistently meets the requirement that the curing process should commence as early as possible because the period between the production of the concrete products and their placement in the large curing chamber is very short. Furthermore, all products stored in the large chamber are exposed to the same climate.

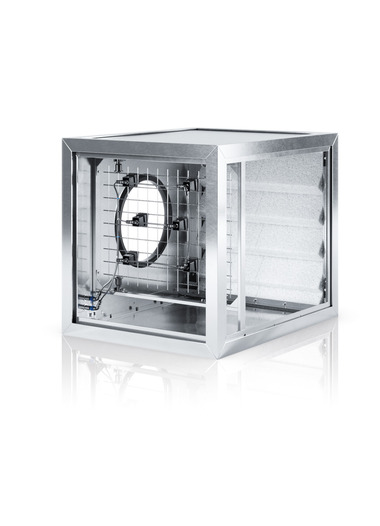

In the case of separate chambers, only the curing rack is insulated and divided into individual chambers by insulated partitions (Fig. 4). Roll-up doors usually close the point of access to the chambers. The curing temperatures reached in the individual chambers exceed those in large curing chambers. Various curing programs can be run when using heating and humidification systems. However, the process of placing products in the chamber can take several hours, which is why there is a higher risk of initial water evaporation.

Chamber insulation

The housing of the curing racks must be fitted with an effective insulation because the saturation temperature is only 0.8° C below the chamber temperature at a humidity of 95% and a temperature of 25° C. Without insulation, the prevailing humidity would lead to condensation on the walls and ceiling of the chamber. As a result, dripping water is formed on the ceiling and causes staining when it drops onto the products. Also, puddles may accumulate on the floor.

Although the housing of curing racks leads to higher average air temperatures and humidities, climatic variations in the chambers may be very significant particularly in the summer season. Exposure to sunlight and the dissipation of the heat of hydration cause heat to accumulate underneath the chamber ceiling. The resulting vertical temperature gradient may amount to more than 15° C. Consequently, products may exhibit color variations, and the degree of hydration may vary significantly when comparing items stored at the top and bottom levels. For this reason, it is advisable to install an air recirculation system to ensure a uniform climate in the curing rack and to fully utilize the benefits of housed curing racks.

Air recirculation systems

Air recirculation systems mainly aim to generate a uniform climate for all products stored in the curing chamber. At the same time, they enhance the degree of protection of electronic components and of the steel framework. Such systems should be capable of extracting a certain portion of the humidity from the rack because of the risk of dripping water forming on the chamber ceiling when the air has reached its saturation point.

A uniform climate in the chamber is achieved by a sufficient degree of air circulation. This is ensured by appropriate piping that is usually mounted on the rear wall of the racks (Fig. 4). A propeller fan draws the air off the rack and injects it into the space underneath the lowermost board level. It is important that every aisle is fitted with such an injection system and that the air extraction performed at the ceiling level extends across the entire chamber depth. This set-up prevents climatic variations from occurring far inside the chamber that would otherwise result from limited air circulation due to the products stored in the rack. In addition, the risk of dripping water formation on the chamber ceiling is reduced even further. The air circulation system is supported by ceiling fans installed in the finger car and elevator/lowerator area. These fans extract the heat that has built up underneath the ceiling and blow it to the bottom.

A better curing climate

Humidity sensors fitted below the ceiling set the maximum humidity in the curing rack to a predetermined value. When the defined threshold is exceeded, the excess humidity is blown out of the chamber by exhaust fans in the rear area of the rack. At the same time, less humid fresh air flows into the chamber via the openings at the elevator/lowerator unit. This method mitigates the risk of product re-humidification and condensation.

The time needed to achieve the required degree of hydration is determined by the most unfavorable climatic conditions in the curing chamber. Air recirculation systems specifically improve the curing climate at the lowermost product storage levels. Their use results in either a shortening of the curing time or better protection of the products against transport damage due to the development of higher strengths. As a result of installing a housing combined with an air recirculation system, customers were able to extend the production period in the year by up to two weeks before having to shut down production because of poor ambient conditions.

Air humidification in curing racks

Humidity is not always identical in all zones of the curing rack, but is subject to fluctuations caused by the production process or ambient conditions. Particularly in one-shift operation, the air temperature and humidity inside the chamber may decrease significantly during production breaks at night or during weekends (Fig. 2). This is mainly reflected by increased efflorescence occurring on the product surface.

In the curing phase, the humidity in unheated chambers is the key parameter to ensure a high product quality. To account for this situation, the relative humidity prevailing in the curing chamber should be stabilized between 80 and 90%. Various air humidification systems are available for use under exceedingly dry ambient conditions. The particular feature of these systems is that they only increase the humidity in the chamber, but not the product or chamber temperature, which is why their operating costs are relatively low. Tried and tested for this purpose are electrically operated steam humidifiers that feed water vapor into the air circulation loops via nozzles.

Water supply and steam curing

systems

Alternatively, there are systems that spray a very finely spread water mist into the chamber via nozzles. However, these systems extract the energy needed for steam generation from the air inside the chamber. This causes cooling of the chamber space and a slow-down of the hydration process.

Furthermore, there are steam curing systems that feed humid, hot air into the curing chambers. Their operation, however, does not only result in an increase in humidity but also heats up the products and leads to condensation on the product surfaces. Also, the operating costs of such systems are higher than those of pure air humidification systems.